PRODUCTS DESCRIPTION

The chemical composition of Incoloy 800 alloy consists mainly of nickel, chromium and iron. Among them, nickel is the main element that improves the corrosion resistance of the alloy, chromium helps enhance the oxidation resistance and high-temperature strength of the alloy, and iron provides the matrix structure of the alloy. In addition, the alloy also contains certain amounts of elements such as carbon, silicon and manganese to further enhance its overall performance. Incoloy 800 coil has very good corrosion resistance, especially in reducing and oxidizing media. It also has good resistance to chemicals such as sulfuric acid, hydrochloric acid and alkaline solutions in high temperature environments. Incoloy 800 coil has good oxidation resistance in high temperature environments and can work at temperatures up to 1100°C for a long time. Lastly, Incoloy 800 coil has high yield strength and creep strength and can maintain its mechanical properties in high and low temperature environments.

Product Parameters

Product Name | Incoloy 800 Coil |

Thickness | 2.5mm-10.0 mm |

Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

Width | 610-2000 mm |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

Certificate | ISO, SGS, BV |

Production Technology | Hot Rolling, Cold Rolling |

Chemical Composition

C | Al | Si | S | Ti | Cr | Mn | Fe | Ni | Cu |

0.1 max | 0.15 - 0.60 | 1.0 max | 0.015 max | 0.15 - 0.60 | 19.0 - 23.0 | 1.5 max | 39.5 min | 30.0 - 35.0 | 0.75 max |

Mechanical Properties

Tensile Strength (ksi) | 0.2% Yield Strength (ksi) | Elongation% in 2 inches |

75 | 30 | 30 |

Physical Performance

Units | Temperature in°C | |

Density | 7.94 g/cm³ | Room |

Specific Heat | 0.11 Kcal/kg.C | 21° |

Melting Range | 1357-1385°C | - |

Modulus of Elasticity | 196.5 KN/mm² | 20° |

Electrical Resistivity | 98.9 µΩ.cm | 20° |

Coefficient of Expansion | 14.4 µm/m °C | 20 - 100° |

Thermal Conductivity | 11.5 w/m-° K | 20° |

Scope of Application

The most common applications are heat treatment equipment, petrochemical pyrolysis piping systems, electric heating unit jackets and food processing equipment.

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

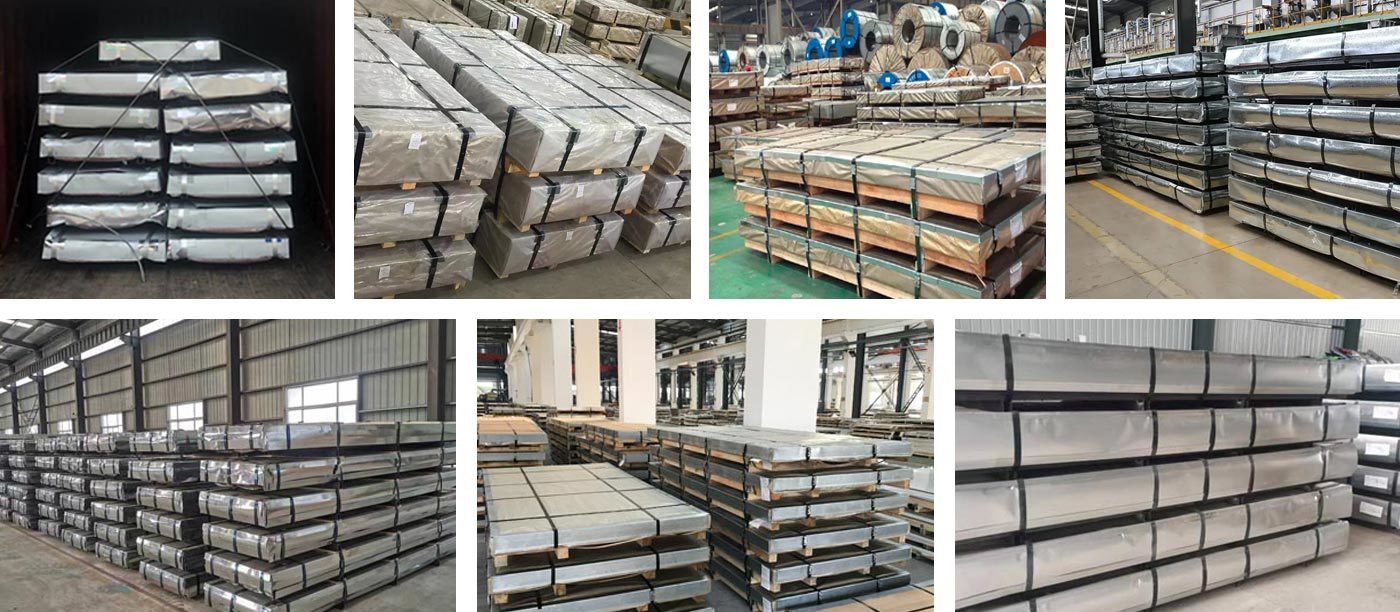

PACKING AND DELIVERY

PRODUCT TESTING

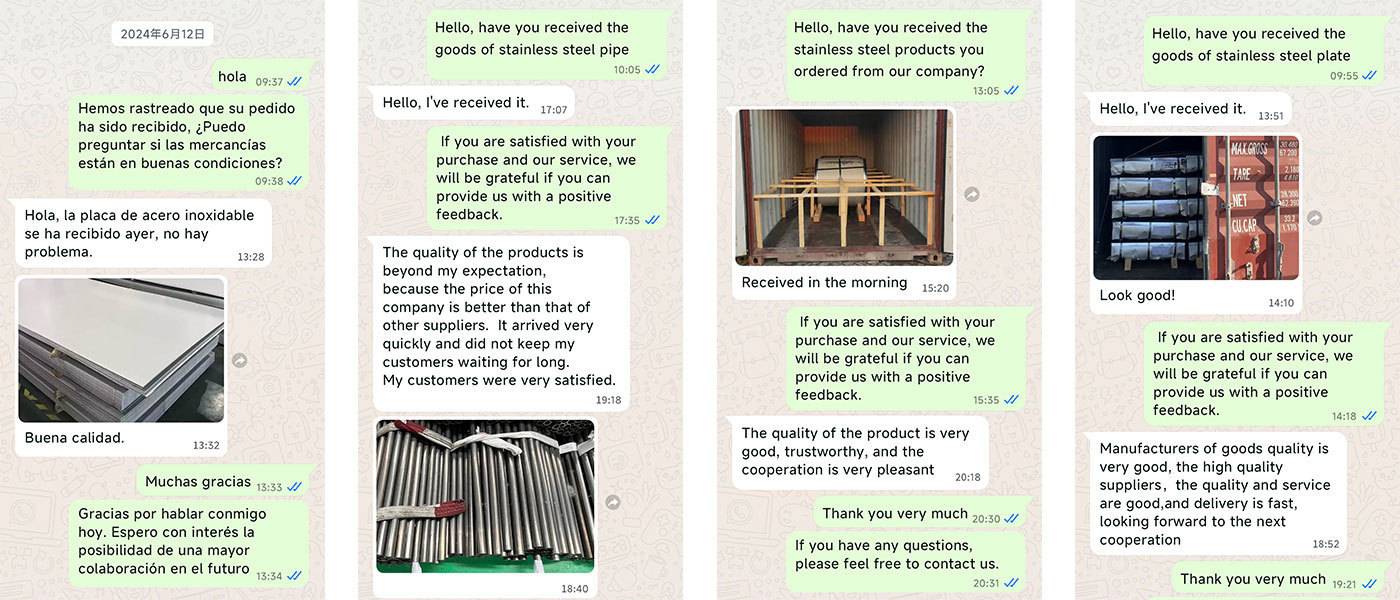

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER