PRODUCTS DESCRIPTION

Monel 400 is a corrosion-resistant alloy with the largest dosage, the most wide range of uses, and excellent comprehensive properties. This alloy has excellent corrosion resistance in hydrofluoric acid and fluorine gas media, and also has excellent corrosion resistance against hot concentrated alkali liquid. It is also resistant to corrosion from neutral solutions, water, seawater, atmosphere, organic compounds, etc. An important feature of this alloy is that it generally does not produce stress corrosion cracking and has good cutting performance. Monel 400 pipe is widely used in many corrosive applications, particularly in the marine and chemical industries. Monel 400 can be easily machined through conventional machining operations.

Product Parameters

Product Name | Monel 400 Pipe | |

Outer Diameter | Round Pipe | 4mm-200mm |

Square Pipe | 10*10mm-100*100mm | |

Rectangular Pipe | 10*20mm-50*100mm | |

Wall Thickness | 0.6mm-6.0mm | |

Length | 1-6 meters, Length can be customized | |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, No.4, BA, etc. | |

Certificate | ISO, SGS, BV | |

Production Technology | Hot Rolling, Cold Rolling | |

Chemical Composition

| Nickel, minA | Copper | lron, max | Manganese, max | Carbon, max | Silicon, max | Sulfur, max |

| 63.0% | 28.0% - 34.0% | 2.5% | 2.0% | 0.3% | 0.5% | 0.024% |

Mechanical Properties

Tensile Strength (ksi) | 0.2% Yield Strength (ksi) | Elongation% in 2 inches |

85 | 35 | 30 |

Physical Performance

Units | Temperature in°C | |

Density | 8.14 g/cm³ | Room |

Specific Heat | 0.105 Kcal/kg.C | Room |

Melting Range | 1370-1400°C | - |

Modulus of Elasticity | 196 KN/mm² | 20° |

Electrical Resistivity | 113 µΩ.cm | 25° |

Coefficient of Expansion | 14.1 µm/m °C | 25 - 100° |

Thermal Conductivity | 11.1 w/m-° K | 25° |

Scope of Application

Used in marine engineering, chemical and hydrocarbon processing equipment, gasoline tanks and fresh water tanks, crude oil distillers, degassing heaters, boiler feed water heaters and other heat exchangers, valves, pumps, shafts, accessories and fasteners, Industrial heat exchangers, chlorinated solvents, crude oil distillation columns, etc.

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

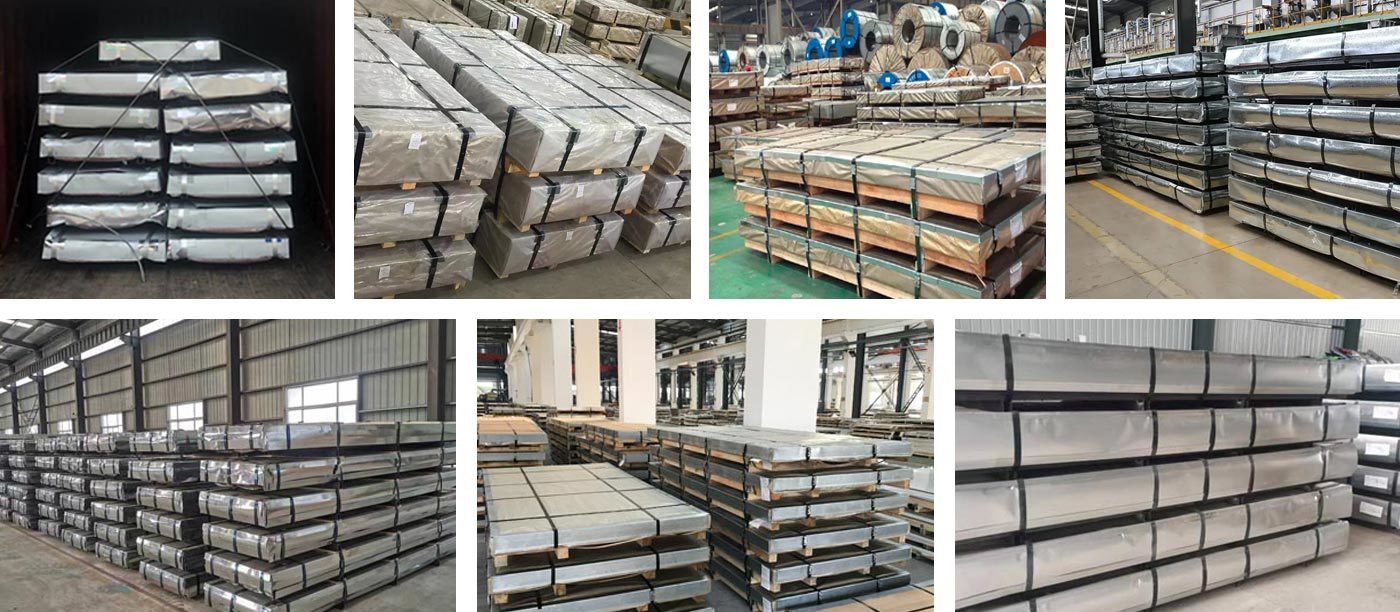

PACKING AND DELIVERY

PRODUCT TESTING

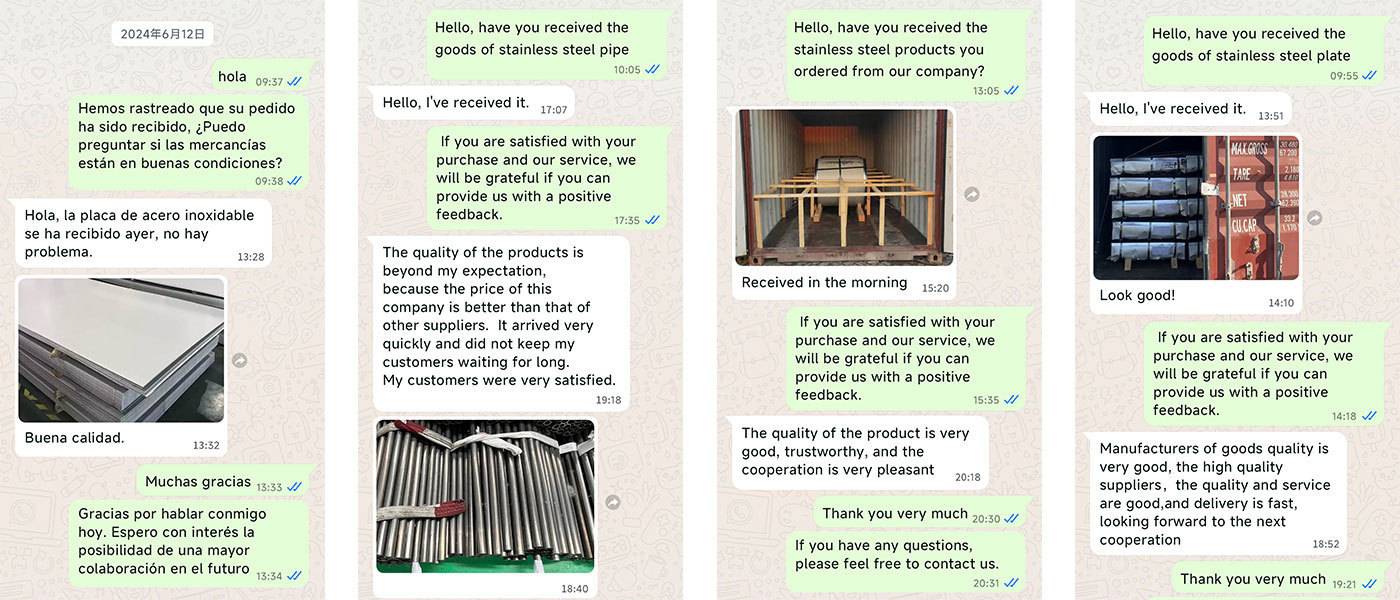

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER