PRODUCTS DESCRIPTION

5083 aluminum is featured by high strength, high plasticity and great corrosion resistance. It has good plasticity during semi-cold work hardening and cold work. As a high-magnesium alloy material, it is widely favored for having good strength, corrosion resistance, and machinability among non-heat-treatable alloys. The main alloying element in 5083 aluminum bar is magnesium, which is associated with good corrosion resistance and weldability, as well as medium strength. Excellent corrosion resistance makes 5083 alloy widely used in maritime applications such as ships, as well as automobiles, aircraft welding parts, subways and light rails, and pressure vessels that require strict fire protection.

Product Parameters

Diameter | 5-650mm or customized | Length | 100-2000mm or customized |

Certificate | ISO, SGS, BV | ||

Standard | JIS, AISI, ASTM, GB, DIN, EN, etc. | ||

Brand | 1000 Series: 1050, 1060, 1070, 1100, 1200, 1235, etc. 3000 Series: 3003, 3004, 3005, 3104, 3105, 3A21, etc. 5000 Series: 5005, 5052, 5083, 5086, 5154, 5182, 5251, 5754, 5A05, etc. 6000 Series: 6061, 6063, 6082, 6A02, etc. 7000 Series: 7050, 7475, 7075, etc. 8000 Series: 8A06, 8011, 8090, etc. | ||

Surface | Coating, Embossing, Drawing, Polishing, Anodizing, etc. | ||

OEM Service | Punching, Cutting special size, Making flat surface, Surface treatment, etc. | ||

Delivery Time | Received 30% after deposit 7-15 working days | ||

Application | Construction, Shipbuilding, Decoration, Industry, Manufacturing, Machinery, Hardware and other fields | ||

Sample | Free Offers Sample | ||

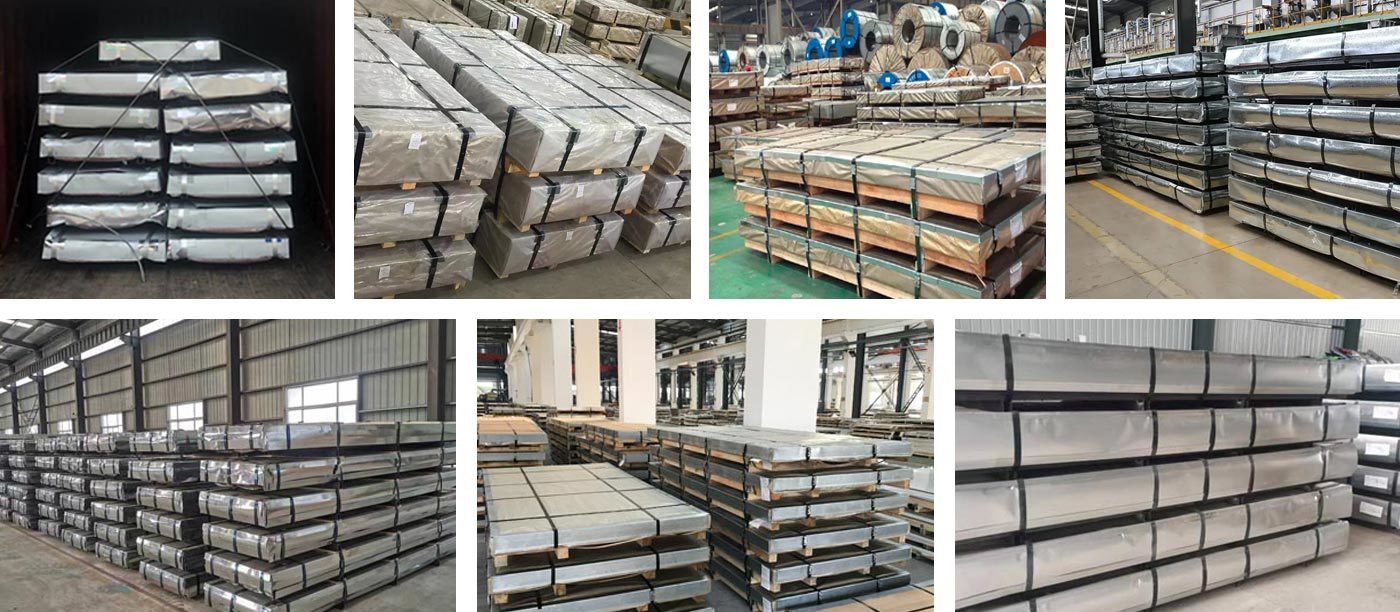

Packaging | Strapping, Plastic bag, Film, Wooden pallet Standard seaworthy export packing or according to customer requirement | ||

Chemical Composition

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each | Others: Total | Al: Min. |

1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.03 | 0.03 | - | 99.50 |

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.60 |

1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | - | 0.04 | 0.03 | 0.05 | - | 99.70 |

1100 | 0.95 Si Fee | 0.05~0.20 | 0.05 | - | - | 0.1 | - | 0.05 | 0.15 | 99.0 | |

2014 | 0.5~1.2 | 0.7 | 3.9~5.0 | 0.4~1.2 | 0.2~0.8 | 0.10 | 0.25 | 0.15 | 0.05 | 0.15 | Allowance |

2017 | 0.2~0.8 | 0.7 | 3.5~4.5 | 0.4~1.0 | 0.4~0.8 | 0.10 | 0.25 | 0.15 | 0.05 | 0.15 | 91.5 - 95.5 |

2024 | 0.50 | 0.50 | 3.8~4.9 | 0.3~0.9 | 1.2~1.8 | 0.10 | 0.25 | 0.15 | 0.05 | 0.15 | Allowance |

3003 | 0.60 | 0.70 | 0.05~0.20 | 1.0~1.5 | - | - | 0.10 | - | 0.05 | 0.15 | Allowance |

3A21 | 0.60 | 0.70 | 0.20 | 1.0-1.6 | 0.05 | - | 0.15 | 0.1-0.2 | - | - | Allowance |

3004 | 0.30 | 0.70 | 0.25 | 1.0~1.5 | 0.8~1.3 | - | 0.25 | - | 0.05 | 0.15 | Allowance |

3005 | 0.60 | 0.70 | 0.30 | 1.0~1.5 | 0.2~0.6 | 0.10 | 0.25 | 0.10 | 0.05 | 0.15 | Allowance |

3105 | 0.60 | 0.70 | 0.30 | 0.3~0.8 | 0.2~0.8 | 0.20 | 0.40 | 0.10 | 0.05 | 0.15 | Allowance |

5005 | 0.30 | 0.70 | 0.20 | 0.20 | 0.5~1.1 | 0.1 | 0.25 | - | 0.05 | 0.15 | Allowance |

5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2~2.8 | 0.15~0.35 | 0.10 | - | 0.05 | 0.15 | Allowance |

5754 | 0.40 | 0.40 | 0.10 | 0.50 | 2.6~3.6 | 0.30 | 0.20 | 0.15 | 0.05 | 0.15 | Allowance |

5A05 | 0.50 | 0.50 | 0.10 | 0.3-0.6 | 4.8-5.5 | - | 0.20 | - | 0.05 | 0.05 | Allowance |

5083 | 0.40 | 0.40 | 0.10 | 0.4~1.0 | 4.0~4.9 | 0.05~0.25 | 0.25 | 0.15 | 0.05 | 0.15 | Allowance |

6061 | 0.40~0.8 | 0.70 | 0.15~0.4 | 0.15 | 0.8~1.2 | 0.04~0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Allowance |

6082 | 0.70~1.3 | 0.50 | 0.10 | 0.4~1.0 | 0.6~1.2 | 0.25 | 0.20 | 0.10 | 0.05 | 0.15 | Allowance |

7075 | 0.40 | 0.50 | 1.2~2.0 | 0.30 | 2.1~2.9 | 0.18~0.28 | 5.1~6.1 | 0.20 | 0.05 | 0.15 | Allowance |

Mechanical Properties

Tensile Strength (MPa) | Yield Strength (MPa) | Elongation Rate (%) | Hardness (HV) |

290 | 145 | 22 | 87 |

Physical Performance

Density | Melting Point | Modulus of Elasticity | Thermal Conductivity |

2.65 Kg/m³ | 591-638 °C | 70.3 GPa | 117 W/m.K |

Annealing State

Brand | Annealing State |

1xxx: 1050, 1050A, 1060, 1100 | O, H12, H14, H16, H18, H22, H24, H26, H28, H111 |

3xxx: 3003, 3004, 3005, 3105 | |

5xxx: 5005, 5052, 5754, 5083, 5086, 5182, 5049, 5251, 5454 | O, H22, H24, H26, H28, H32, H34, H36, H38, H111 |

6xxx: 6061, 6082 | T4, T6, T451, T651 |

2xxx: 2024 | T3, T351, T4 |

7xxx: 7075 | T6, T651 |

Scope of Application

Aluminum Uses And Application Area | |

Food Packaging | Beverage can ends, cans, bottle caps, etc. |

Building | Curtain walls, cladding, suspended ceilings, thermal insulation, venetian blinds, etc. |

Transportation | Auto parts, passenger car bodies, aviation ships and air cargo containers. |

Electronic Equipment | Electrical appliances, communication equipment,PCPlate drilling guide, lighting and heat dissipation materials, etc. |

Consumer Goods | Umbrellas, cooking utensils, sports equipment, etc |

Other | Military, color coated aluminum plate |

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

PACKING AND DELIVERY

PRODUCT TESTING

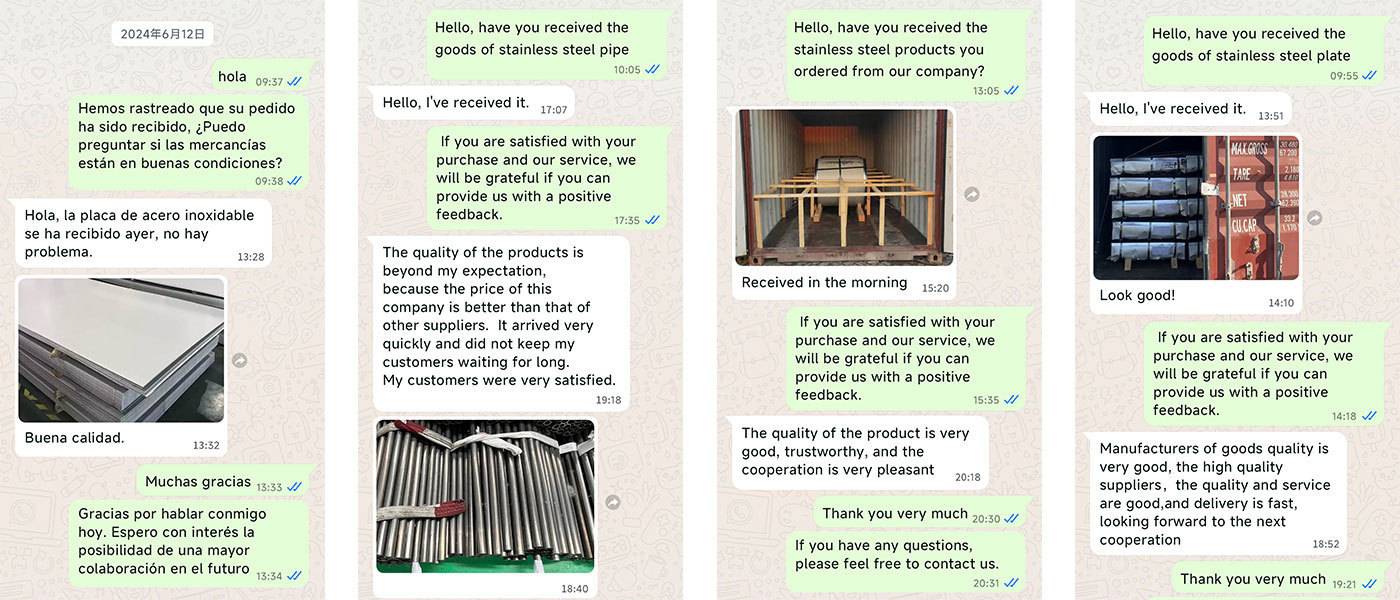

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER