PRODUCTS DESCRIPTION

Under normal conditions, AISI1025 steel bars exhibit good corrosion resistance. Because of its lower carbon content, it is less resistant to corrosion than stainless steel and high-strength alloy steel. However, under the right conditions, the corrosion resistance of AISI1025 parts can be improved by surface treatment with a thin film. AISI1025 can also be heat treated to increase its strength and hardness. Heat treatment can be achieved by quenching and tempering the steel at high temperatures. AISI1025 steel bars are often used in the manufacture of bolts, nuts and other mechanical industrial parts. The steel has good processability and is easy to weld. In addition, the hardness of AISI1025 steel is also easy to control, making it one of the commonly used materials for manufacturing metal parts.

Product Parameters

Product Name | AISI/SAE 1025 Round Steel Bar | |||

Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI, etc. | |||

Common Round Bar Specifications | 3.0-50.8 mm, Over 50.8-300mm | |||

Flat Steel Common Specifications | 6.35x12.7mm, 6.35x25.4mm, 12.7x25.4mm | |||

Hexagon Bar Common Specifications | AF5.8mm-17mm | |||

Square Bar Common Specifications | AF2mm-14mm, AF6.35mm, 9.5mm, 12.7mm, 15.98mm, 19.0mm, 25.4mm | |||

Length | 1-6meters, Size Accept Custom | |||

Diameter(mm) | Hot Rolling Round Bar | 25-600 | Cold Rolling Square Bar | 6-50.8 |

Hot Rolling Square Bar | 21-54 | Cold Rolling Hexagon Bar | 9.5-65 | |

Cold Rolling Round bar | 6-101.6 | Forged Rebar | 200-1000 | |

Surface Process | Bright, Polished, Black | |||

Other Services | Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. | |||

Chemical Composition

1025 | C | Si | Mn | S | P | Cr | Ni | Cu |

0.62-0.70 | 0.17-0.37 | 0.90-1.20 | ≤ 0.035 | ≤ 0.035 | ≤ 0.25 | ≤ 0.25 | ≤ 0.25 |

Mechanical Properties

1025 | Tensile Strength | Yield Strength | Elongation | Reduction of Area | Hardness | |||

(Mpa) | (Mpa) | (%) | (%) min | Hot Rolled | Cold Rolled Soft | Cold Rolled Hard | Heat Treatment | |

825-925 | 520-690 | 14-21.5 | 10 | 240-270 HB | 190-220 HB | 300-340 HB | 38-60 HRC | |

Scope of Application

SAE 1025 is a low-carbon steel with excellent corrosion resistance, heat resistance and mechanical properties. It can be used in a wide range of applications from auto parts to building materials.

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

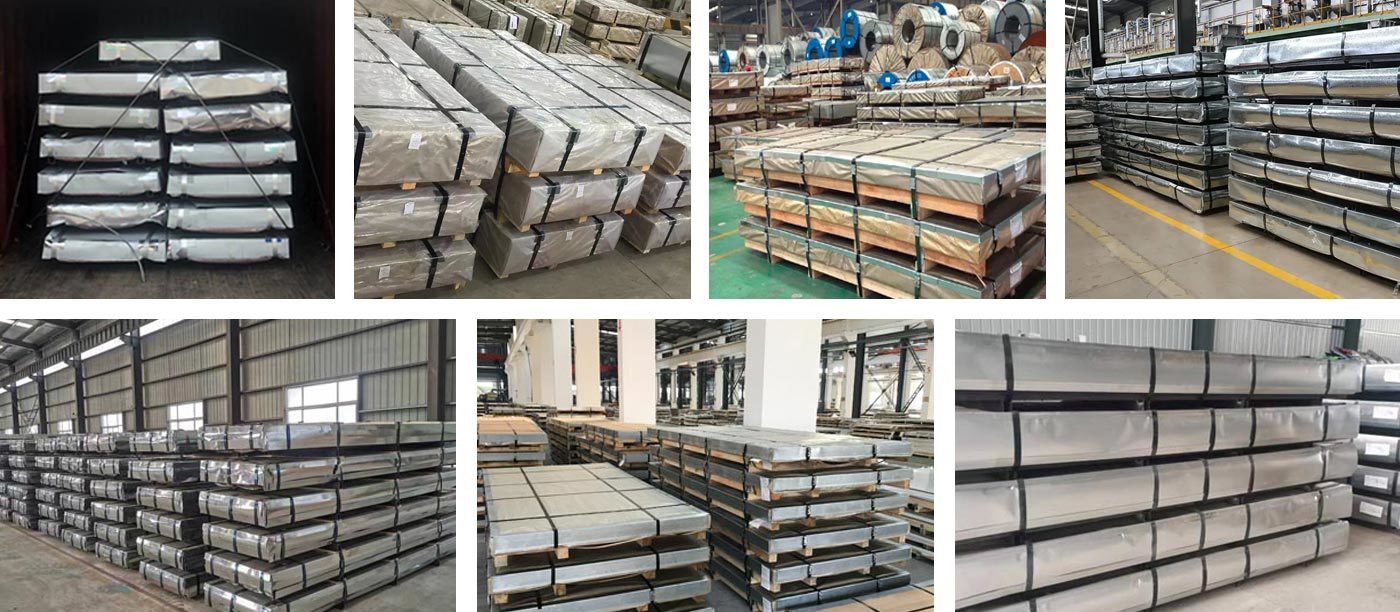

PACKING AND DELIVERY

PRODUCT TESTING

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER