PRODUCTS DESCRIPTION

1008 cold rolled steel coil contains about 1.2% manganese and 0.4% silicon. There are also nickel, aluminium, chromium, copper and molybdenum present in small quantities in the carbon steels. AISI 1008 carbon steel coil has excellent weldability, which includes projection, butt, spot and fusion, and brazeability. 1008 cold rolled steel coil is mainly used in automobile, printed metal pail, building, building materials, and bicycle, etc. Besides, it is the best material to manufacture organic coated strip.

Product Parameters

Product Name | 1008 Cold Rolled Steel Coil |

Production Process | Hot Rolling, Cold Rolling |

Material Standards | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

Width | 100mm-3000mm |

Length | 1m-12m, or Customized Size |

Thickness | 0.1mm-400mm |

Delivery Conditions | Rolling, Annealing, Quenching, Tempered or Standard |

Surface Process | Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

| Element | Content (%) |

|---|---|

| Iron, Fe | 99.31-99.7 % |

| Manganese, Mn | 0.30-0.50 % |

| Carbon, C | 0.10 % |

| Sulfur, S | 0.050 % |

| Phosphorous, P | 0.040 % |

Mechanical Properties

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 340 MPa | 49300 psi |

| Yield strength (depending on temper) | 285 MPa | 41300 psi |

| Elastic modulus | 190-210 Gpa | 27557-30458 ksi |

| Bulk modulus (typical for steel) | 200 GPa | 29000 ksi |

| Shear modulus (typical for steel) | 80.0 GPa | 11600 ksi |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Elongation at break (in 50 mm) | 20 % | 20 % |

| Reduction of area | 45 % | 45 % |

| Hardness, Brinell | 95 | 95 |

| Hardness, Knoop (converted from Brinell hardness) | 113 | 113 |

| Hardness, Rockwell B (converted from Brinell hardness) | 55 | 55 |

| Hardness, Vickers (converted from Brinell hardness) | 98 | 98 |

Machinability (based on AISI 1212 steel as 100 machinability) The machinability of group I bar, rod, and wire products can be improved by cold drawing) | 55 | 55 |

Scope of Application

AISI 1008 carbon steel is primarily used in extruded, cold headed, cold upset, and cold pressed parts and forms.

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

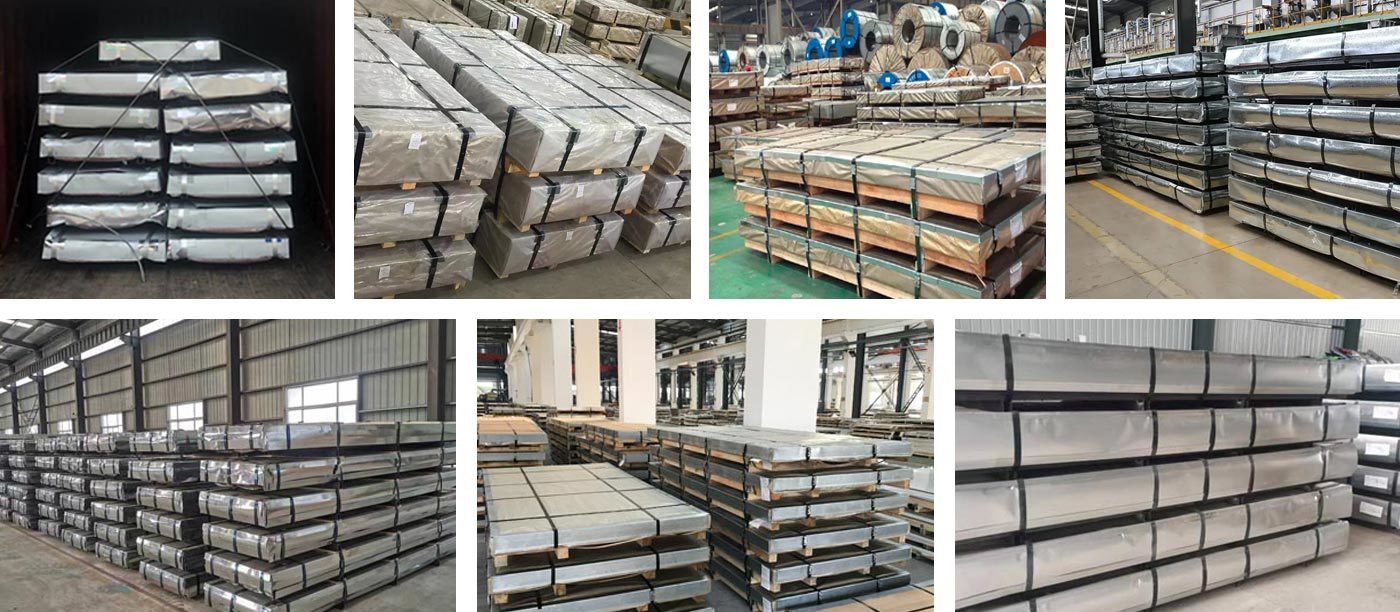

PACKING AND DELIVERY

PRODUCT TESTING

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER