PRODUCTS DESCRIPTION

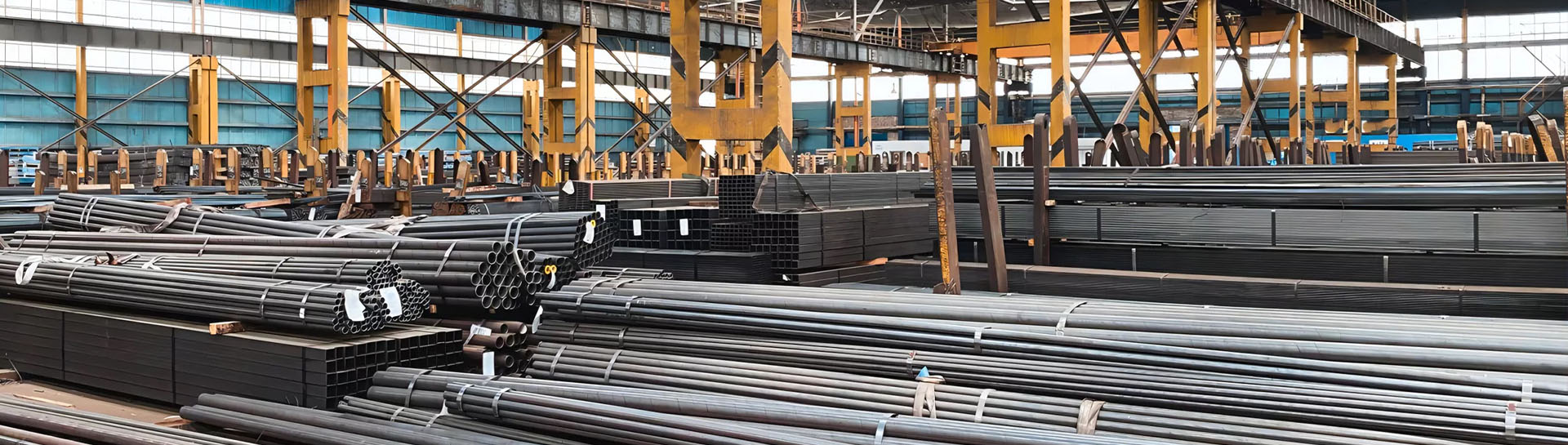

A203 boiler container coils are available in five grades: Grade A, Grade B, Grade D, Grade E, and Grade F. The chemical composition shall conform to the requirements of ASTM A203/A203M. At the same time, ASTM A203 boiler container coil is subject to two mechanical properties test: namely tensile test and impact test after production. This kind of coil is widely used in petroleum, chemical industry, power station, boiler and other industries, for the manufacture of reactor, heat exchanger, separator, spherical tank, oil and gas tank, high pressure pipeline, water turbine and other equipment and components.

Product Parameters

Product Name | A203 Pressure Vessel Carbon Steel Coil |

Production Process | Hot Rolling, Cold Rolling |

Material Standards | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

Width | 45mm-2200mm |

Length | Custom Size |

Thickness | Hot Rolling: 2.75mm-100mm |

Delivery Conditions | Rolling, Annealing, Quenching, Tempered or Standard |

Surface Process | Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

A203 | Upper Limit of Chemical Element Content (%) | |||||

C | Si | Mn | P | S | Ni | |

Class A | 0.23 | 0.13-0.45 | 0.88 | 0.025 | 0.025 | 2.03-2.57 |

Class B | 0.25 | 0.13-0.45 | 0.88 | 0.025 | 0.025 | 2.03-2.57 |

Class D | 0.20 | 0.13-0.45 | 0.88 | 0.025 | 0.025 | 3.18-3.82 |

Class E | 0.23 | 0.13-0.45 | 0.88 | 0.025 | 0.025 | 3.18-3.82 |

Class F | 0.23 | 0.13-0.45 | 0.88 | 0.025 | 0.025 | 3.18-3.82 |

Mechanical Properties

A202 | Tensile Strength kis [MPa] | Yield Strength kis [MPa] | Elongation Gauge Length 8in. [200mm], % | Elongation Gauge Length 2in. [50mm], % |

Grade A | 65-85 [450-585] | 37 [255] | 19 | 23 |

Grade B | 70-90 [485-620] | 40 [275] | 17 | 21 |

Grade D | 65-85 [450-585] | 37 [255] | 19 | 23 |

Grade E | 70-90 [485-620] | 40 [275] | 17 | 21 |

Grade F | 75-100 [515-690] | 50 [345] | - | 20 |

Physical Performance

Physical Performance | Metric | Imperial |

Density | 7.80 g/cc | 0.282 lb/in³ |

Scope of Application

ASTM A203 boiler vessel plate is widely used in petroleum, chemical industry, power station, boiler and other industries, for the manufacture of reactor, heat exchanger, separator, spherical tank, oil and gas tank, high pressure pipeline, water turbine and other equipment and components.

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

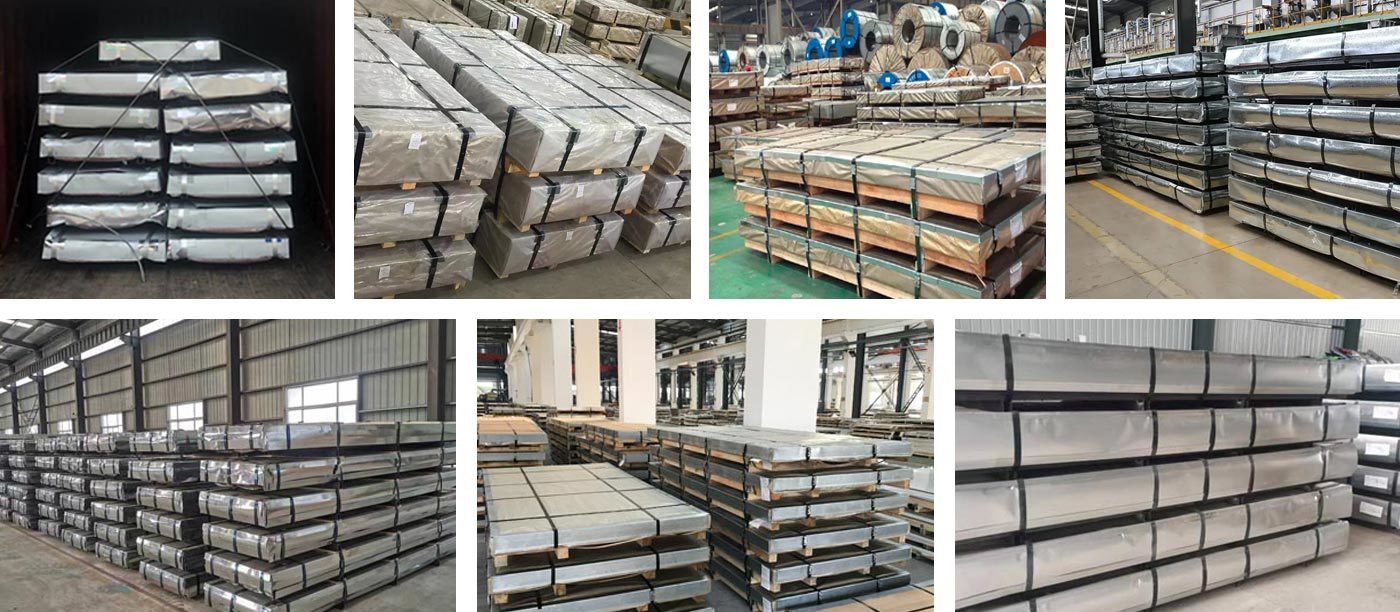

PACKING AND DELIVERY

PRODUCT TESTING

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER