PRODUCTS DESCRIPTION

ASTM A213 or ASME SA213 seamless tube is applicable to seamless ferritic and austenitic pipes with the minimum thickness in boiler and superheater. It is typically used as heating surface pipe, boiler header and steam pipe in low and medium pressure boilers. This seamless steel pipe is widely applied in heat exchanger, condenser and heat transfer equipment. Selecting a steel pipe suitable for a specific application requires comprehensive consideration of multiple factors such as temperature, pressure, flow, material quality, corrosion protection and welding installation to ensure that the steel pipe can operate safely and reliably in the application scenario.

Product Parameters

Product Name | A213 Seamless Carbon Steel Pipe | |

Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI etc. | |

Outer Diameter | Seamless: 1/4"-36" | Welding: 21.3mm-3620mm |

Round Tube: 1/2"-10" | Square Tube/Rectangular Tube: 15x15mm-400x600mm | |

Wall Thickness | Seamless: 1.25mm-50mm | Welding: 1.65mm-65mm |

Length | 3-12 meters, Support customization | |

Surface Process | Bright, Polished, Black | |

Other Services | Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. | |

Chemical Composition

A213 | C | Si | Mn | P,S Max | Cr | Mo | V | Al Max | Nb |

T2 | 0.10-0.20 | 0.10-0.30 | 0.30-0.61 | 0.025 | 0.50-0.81 | 0.44-0.65 | - | - | - |

T11 | 0.05-0.15 | 0.50-1.00 | 0.30-0.60 | 0.025 | 1.00-1.50 | 0.44-0.65 | - | - | - |

T12 | 0.05-0.15 | Max 0.5 | 0.30-0.61 | 0.025 | 0.80-1.25 | 0.44-0.65 | - | - | - |

T22 | 0.05-0.15 | Max 0.5 | 0.30-0.60 | 0.025 | 1.90-2.60 | 0.87-1.13 | - | - | - |

T91 | 0.07-0.14 | 0.20-0.50 | 0.30-0.60 | 0.02 | 8.0-9.5 | 0.85-1.05 | 0.18-0.25 | 0.015 | 0.06-0.10 |

T92 | 0.07-0.13 | Max 0.5 | 0.30-0.60 | 0.02 | 8.5-9.5 | 0.30-0.60 | 0.15-0.25 | 0.015 | 0.04-0.09 |

Mechanical Properties

A213 | Tensile Strength | Yield Strength | Elongation | Hardness |

T2 | ≥ 415 MPa | ≥ 205 MPa | ≥ 30 % | 163 HBW (85 HRB) |

T11 | ≥ 415 MPa | ≥ 205 MPa | ≥ 30 % | 163 HBW (85 HRB) |

T12 | ≥ 415 MPa | ≥ 220 MPa | ≥ 30 % | 163 HBW (85 HRB) |

T22 | ≥ 415 MPa | ≥ 205 MPa | ≥ 30 % | 163 HBW (8 5HRB) |

T91 | ≥ 585 MPa | ≥ 415 MPa | ≥ 20 % | 250 HBW (25 HRB) |

T92 | ≥ 620 MPa | ≥ 440 MPa | ≥ 20 % | 250 HBW (25 HRB) |

Scope of Application

Seamless ferritic and austenitic steel boilers, boiler tubes and heat exchanger tubes for high temperature service.

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

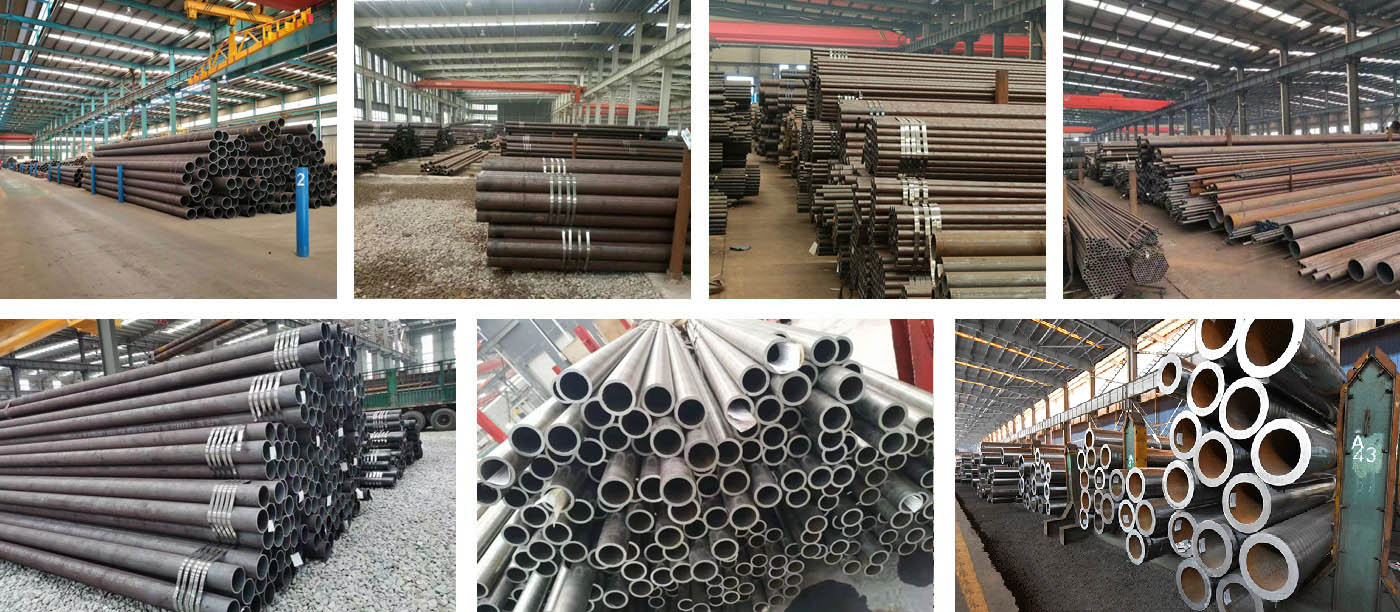

PACKING AND DELIVERY

PRODUCT TESTING

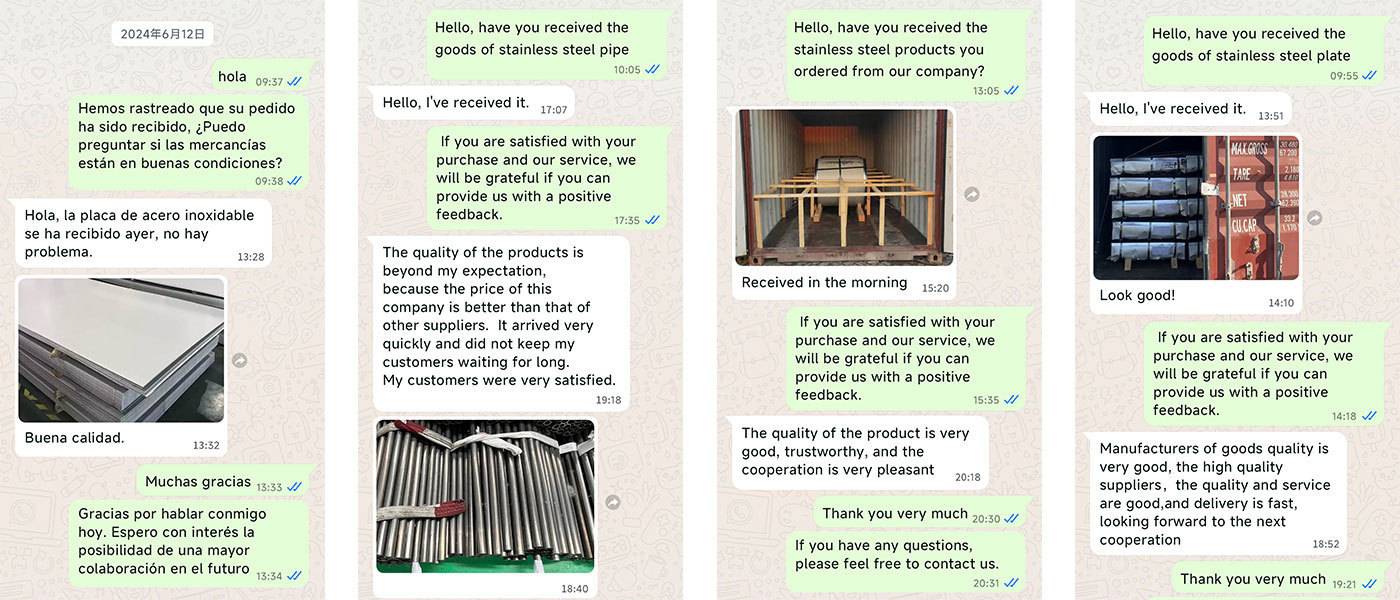

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER