PRODUCTS DESCRIPTION

ERW (Electrical Resistance Welding) pipes are manufactured by cold forming of steel coil into a round cylindrical shape and are used in various engineering purposes. They are round pipes welded from steel plates with longitudinal welds. Pressure welding is carried out under the action of squeeze rollers. The production process of welded steel pipes is simple, the production efficiency is high, the varieties and specifications are many, and the equipment is few, but the general strength is lower than that of seamless steel pipes. ERW pipes are commonly used to transport oil, natural gas and other vapor-liquid objects, and can meet various requirements of high and low pressure.

Product Parameters

Product Name | Resistance Welded Pipe ERW |

Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI etc. |

Outer Diameter | 1/2"-24" |

Wall Thickness | 1.65-20mm |

Length | 3m-12m, Support customization |

End | Flat end, Beveled end, Thread |

Product Material

Standard | Material |

API 5L | PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70 |

ASTM | A53 G R.A, G R.B |

EN | S275, S275JR, S355JRH, S355J2H |

GB | Q195, Q215, Q235, Q345, L175, L210, L245, L320, L360-L555 |

Scope of Application

Used for ERW line pipe, ERW casing, ERW structural pipe, for high pressure and high temperature, etc.

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

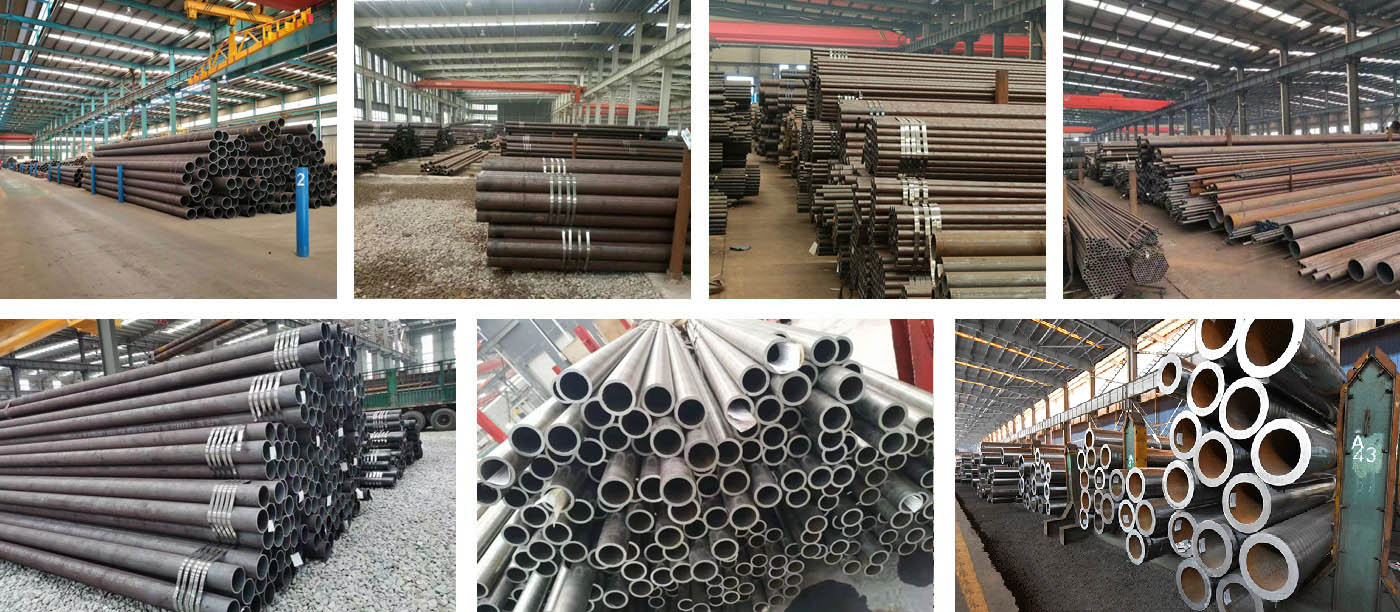

PACKING AND DELIVERY

PRODUCT TESTING

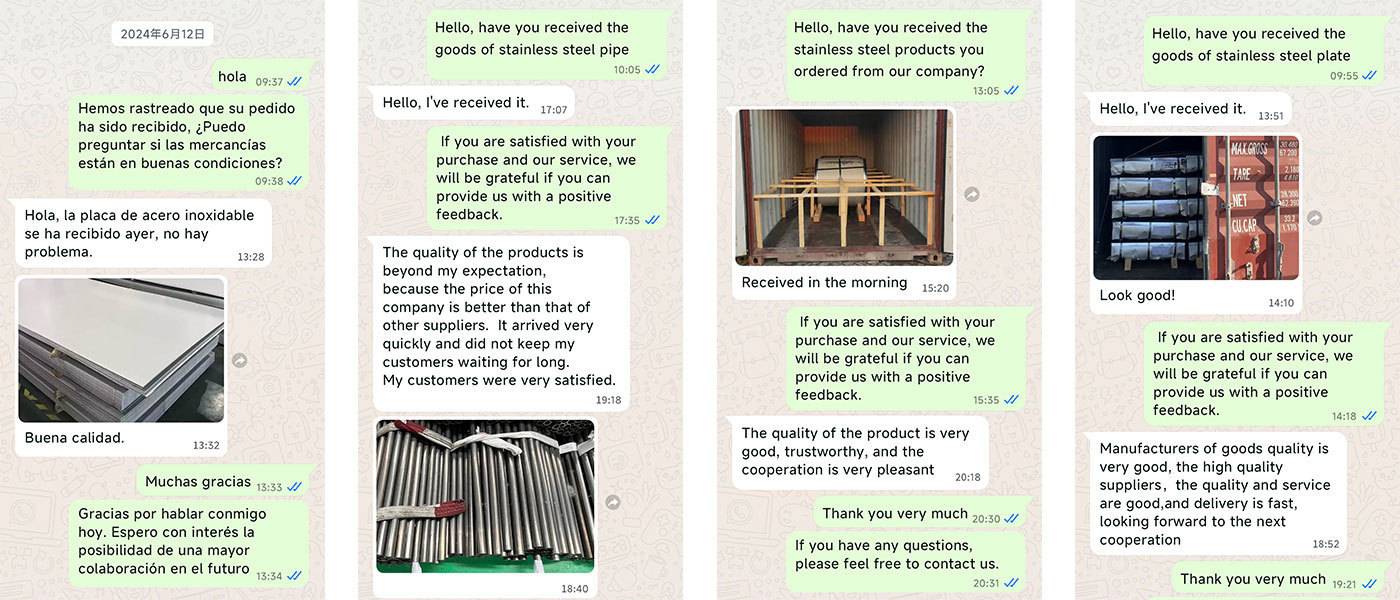

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER