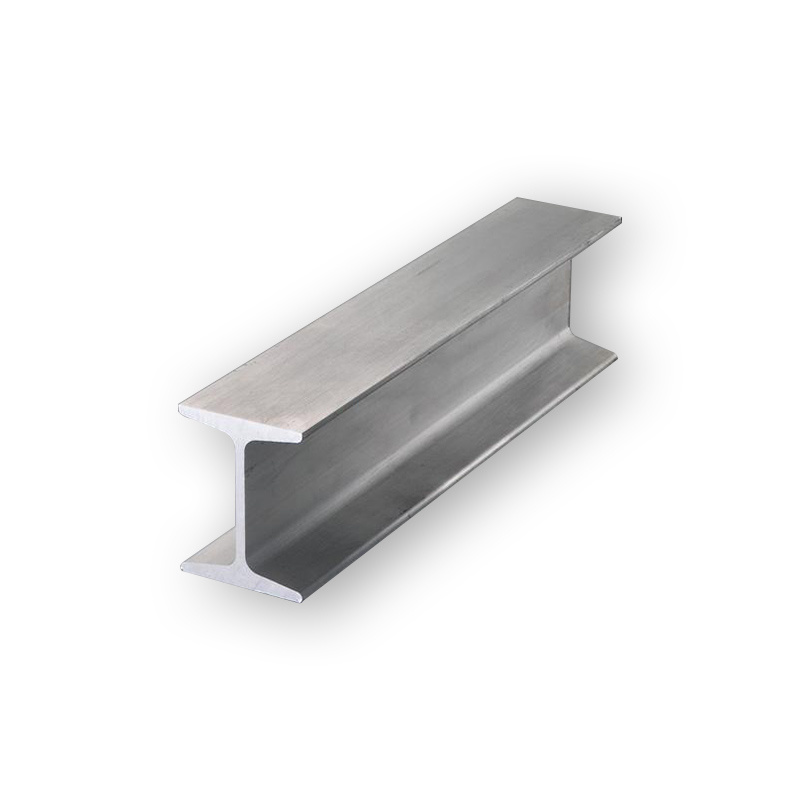

PRODUCTS DESCRIPTION

A Wear-Resistant Steel Plate is made from an alloy of stainless steel that contains at least 0.2 % nickel, aluminum, or copper. It is frequently used in the manufacturing of structural components and tools. The alloy is resistant to wear, corrosion, and rust.

Steel plates that are Wear Resistant Plates are normally produced in their as-rolled condition. These steel plate product types have been created specifically for long service life in challenging environments. Tempering and quenching are used to create wear-resistant steel plates. The formation of crystal structures during the quenching process enhances the material’s strength. Steel produced using this technique has a four times greater resistance to wear.

Product Parameters

Product Name | Wear Resistant Steel Plate (NM Plate) |

Production Process | Cutting, Bending, Polishing, etc. |

Common Grades | NM260, NM300, NM350, NM400, NM450, NM500, NM550, NM600, etc. |

Width | 100mm-3500mm |

Length | 1m-18m, or Customized Size |

Thickness | 0.4mm-80mm |

Surface | Oiled, Black Painted, Shot Blasted, Hot Dipped Galvanized, Checkered, etc. |

Uses of Wear Resistant Plates

Wear Resistant Steel Plates are used in the construction of buildings and bridges in addition to being used for kitchenware and appliances like cutlery and plates. Wear Resistant Plates can be used in a variety of materials, including cast iron, ductile iron, high-carbon steel, low-carbon steel, and stainless steel. These Plates are used in industries where moving components are exposed to impact and abrasion. They can be made from a variety of materials, they provide greater abrasion resistance and can help prevent metal parts from scratching.

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

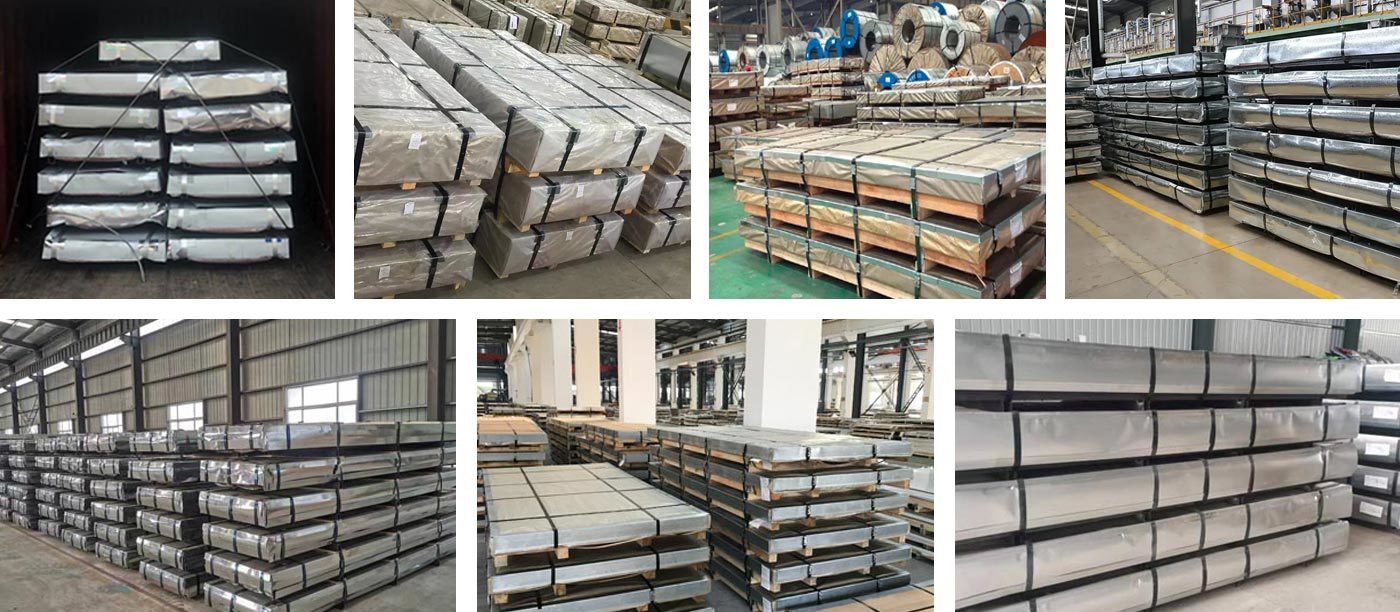

PACKING AND DELIVERY

PRODUCT TESTING

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER