PRODUCTS DESCRIPTION

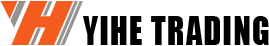

DX53D/SGCD2/SGCD3 Galvanized Coil Description

DX53D galvanized coil is a kind of galvanized steel. The galvanized layer has good corrosion resistance and can effectively protect the steel from corrosion. Besides, DX53D galvanized coil has good processing performance and can be used for shearing, bending, welding, drilling and other processing operations. At the same time, the galvanized layer can also increase the hardness and strength of the steel plate, making it more wear-resistant. Its excellent corrosion resistance and processing properties make it widely used in the construction industry. In addition, galvanized steel coil can also be used to make lightweight steel structures and other components, effectively improving the stability and service life of buildings.

Scope of Application

Galvanizing products are widely used in industry, agriculture, animal husbandry and fishery, energy, transportation, chemical industry, light industry, home appliances, construction, communications, national defense and other fields.

Product Parameters

Product Name | DX53D/SGCD2/SGCD3 Galvanized Coil |

Thickness | 0.12mm-3.5mm |

Width | 600mm-1500mm |

Length | 508mm/610mm, Support Customization |

Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

Zinc Layer | Hot Galvanizing: 60-275g/m² |

Pre-galvanized: 80-275g/m² |

Chemical Composition

Standard | Grade | C | Si | Mn | P | S | Ti |

Forcold Forming Chinese Standard | DX51D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 |

DX52D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

DX53D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

DX54D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

DX56D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

DX57D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

Forcold Forming Japanese Standard | SGCC | 0.15 | 0.50 | 0.80 | 0.050 | 0.030 | 0.025 |

SGCD1 | 0.12 | 0.50 | 0.60 | 0.040 | 0.030 | 0.025 | |

SGCD3 | 0.08 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

SGCD4 | 0.06 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

For Structure Japanese Standard | SGC340 | 0.25 | 0.50 | 1.70 | 0.200 | 0.035 | 0.025 |

SGC400 | 0.25 | 0.50 | 1.70 | 0.200 | 0.035 | 0.150 | |

SGC490 | 0.30 | 0.50 | 2.00 | 0.200 | 0.035 | 0.025 | |

SGC510 | 0.30 | 0.50 | 2.50 | 0.200 | 0.035 | 0.025 | |

For Structure AISI Standard | S220GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 |

S250GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

S280GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

S320GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

S350GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 | |

S550GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 |

Mechanical Properties

Grade | Yield Strength MPa≥ | Tensile Strength MPa≥ | Elongation A%≥ |

DX51D Z/ZM/AZ/AM | 240-380 | 270-500 | 22 |

DX52D Z/ZM/AZ/AM | 140-300 | 270-420 | 26 |

DX53D Z/ZM/AZ/AM | 140-260 | 270-380 | 30 |

DX54D Z/ZM/AZ/AM | 120-220 | 260-350 | 36 |

S220GD Z/ZM/AM | 220 | 300 | 20 |

S250GD Z/ZM/AZ/AM | 250 | 330 | 19 |

S280GD Z/ZM/AM | 280 | 360 | 18 |

S300GD A/AM | 300 | 380 | 18 |

S320GD Z/ZM/AM | 320 | 390 | 17 |

S350GD Z/ZM/AZ/AM | 350 | 420 | 16 |

S450GD A/AM | 450 | 480 | 15 |

S550GD Z/ZM/AZ/AM | 550 | 550 | - |

Galvanized Surface Selection

Zero Spangle | Minimized Spangle | Normal Spangle | Large Spangle |

|

|

|

|

Use of The Environment | Recommended Zinc Thickness |

Indoor Use | Z10 or Z12 (100g/㎡or 120g/㎡) |

Suburbs | Z20 and Painting (200g/㎡) |

Urban or Industrial Area | Z27 (270g/㎡) or G90 (US Standard) and painted |

Coastal Area | Thicker than Z27 (270g/㎡) or G90 (US Standard) and painted |

Punch or Deep Drawing Application | Thicker than Z27 (270grams/㎡) or G90 (US Standard) avoid coating peeling after stamping |

Surface Treatment Type | Code | Features |

Chromic Acid Treatment | C | Good corrosion resistance, suitable for bare state |

Chromic Acid Treatment+Oiling | S | Good corrosion resistance |

Phosphoric Acid Treatment (Including Sealing Treatment) | P | Have a certain corrosion resistance, good paint performance |

Phosphoric Acid Treatment (Including Sealing Treatment)+Oiling | Q | Has a certain corrosion resistance, good paint performance, prevent rust during transportation and storage |

Phosphoric Acid Treatment (Excluding Sealing Treatment) | T | Have a certain corrosion resistance, good paint performance |

Phosphoric Acid Treatment (Excluding Sealing Treatment)+Oiling | V | Has a certain corrosion resistance, good paint performance, and prevent rust |

Oiling | O | Prevent rust during transportation and storage |

No Treatment | M | Suitable for immediate painting |

Material Comparison

Chinese Standard | Japan Standard | European Standard |

DX51D Z/DC51D Z (CR) | SGCC | DX51D Z |

DX52D Z/DC52D Z | SGCD1 | DX52D With |

DX53D Z/DC53D Z/DX54D Z/DC54D Z | SGCD2/SGCD3 | DX53D Z/DX54D Z |

S220/250/280/320/350/550GD Z | SGC340/400/440/490/570 | S220/250/280/320/350GD Z |

DX51D Z/DD51D Z (HR) | SGHC | DX51D Z |

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

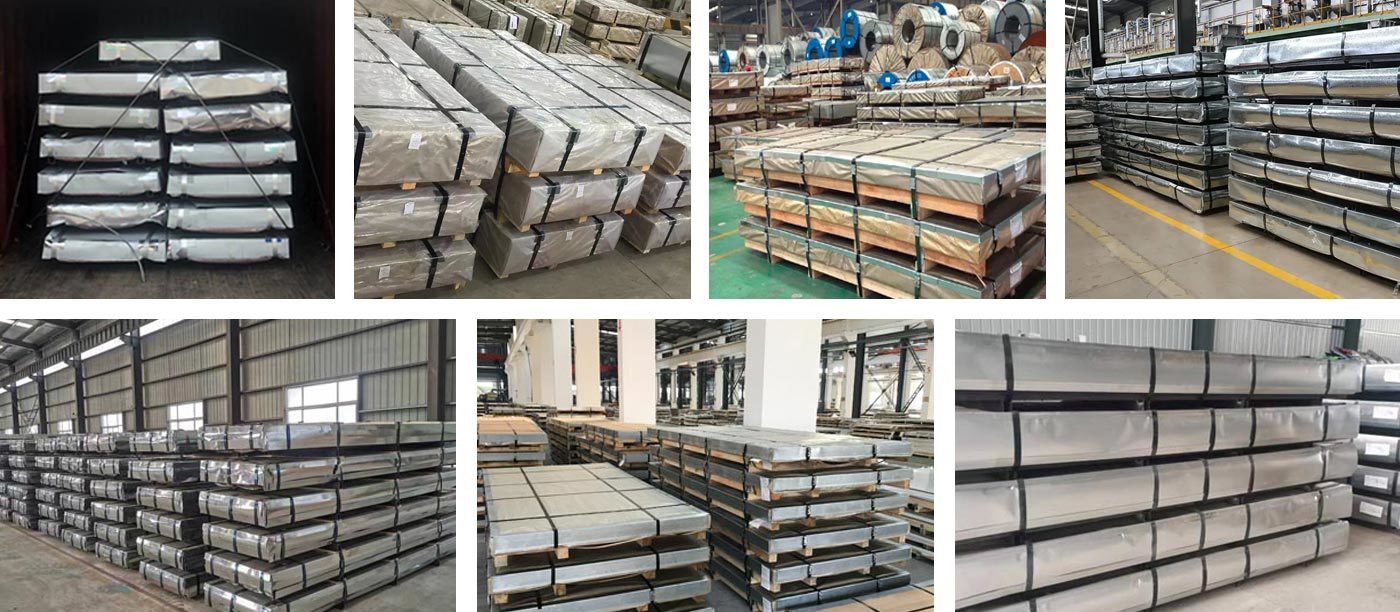

PACKING AND DELIVERY

PRODUCT TESTING

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER