PRODUCTS DESCRIPTION

316L stainless steel pipe has a lower carbon content than 316 stainless steel pipe and is used when welding is needed. The lower carbon content greatly reduces the precipitation of carbides in the heat-affected zone close to the weld, and the precipitation of carbides is strongly associated with intergranular corrosion of stainless steel in some environments. Basically, there is no need to anneal weld joints prior to using the completed metal form. 316L stainless steel pipe is the second most prevalent stainless steel after 304, and it has better corrosion resistance than 304. High temperature resistance is also better, up to 1000 degrees. 316L stainless steel plate is a universal stainless steel material, with better rust resistance than 200 series stainless steel material. 316L stainless steel pipe is widely used in the chemical industry because of its excellent corrosion resistance.

Product Parameters

Product Name | 316L Stainless Steel Pipe | |

Type | Steel Pipe | |

Outer diameter | Round Tube | 4mm-200mm |

Square Tube | 10*10mm-100*100mm | |

Rectangular Tube | 10*20mm-50*100mm | |

Wall Thickness | 0.6mm-6.0mm | |

Length | 1-6 meters, Length can be customized | |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. | |

Scope of Application | Common applications for stainless steel pipes include food processing, Textile operations, Breweries, Water treatment plants, Oil and gas processing, Fertilizers and pesticides, Chemical applications, Construction, Pharmaceuticals, Auto parts, etc. | |

Certificate | ISO, SGS, BV, etc. | |

Production Technology | Hot Rolling, Cold Rolling | |

Edge Processing | Edging, Trimming | |

Chemical Composition

C | Si | Mn | Cr | Ni | S | P | Mo |

≤ 0.03 | ≤1.0 | ≤ 2.0 | 16.0~18.0 | 10.0~14.0 | ≤ 0.03 | ≤ 0.045 | 2.0~3.0 |

Mechanical Properties

Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

≥480 | ≥177 | ≥ 40 | ≤ 187HB;≤ 90HRB;≤ 200HV |

Physical Performance

Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

7.99 | 193 | 16.0 | 16.2 | 74 |

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

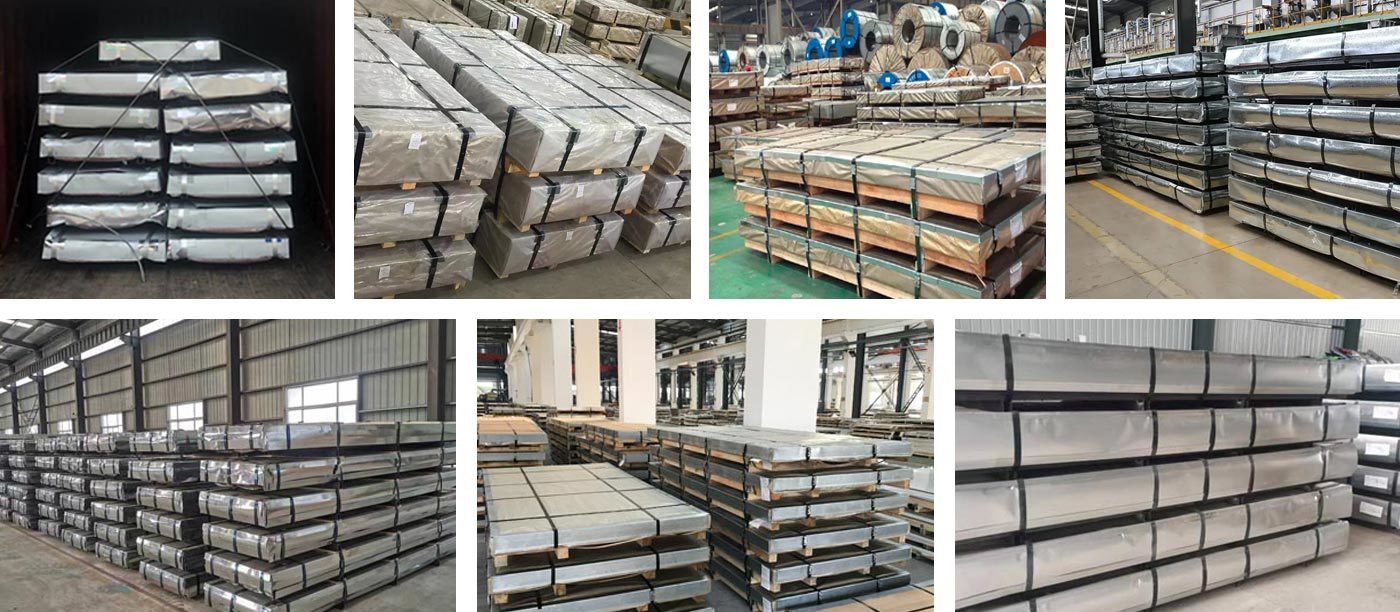

PACKING AND DELIVERY

PRODUCT TESTING

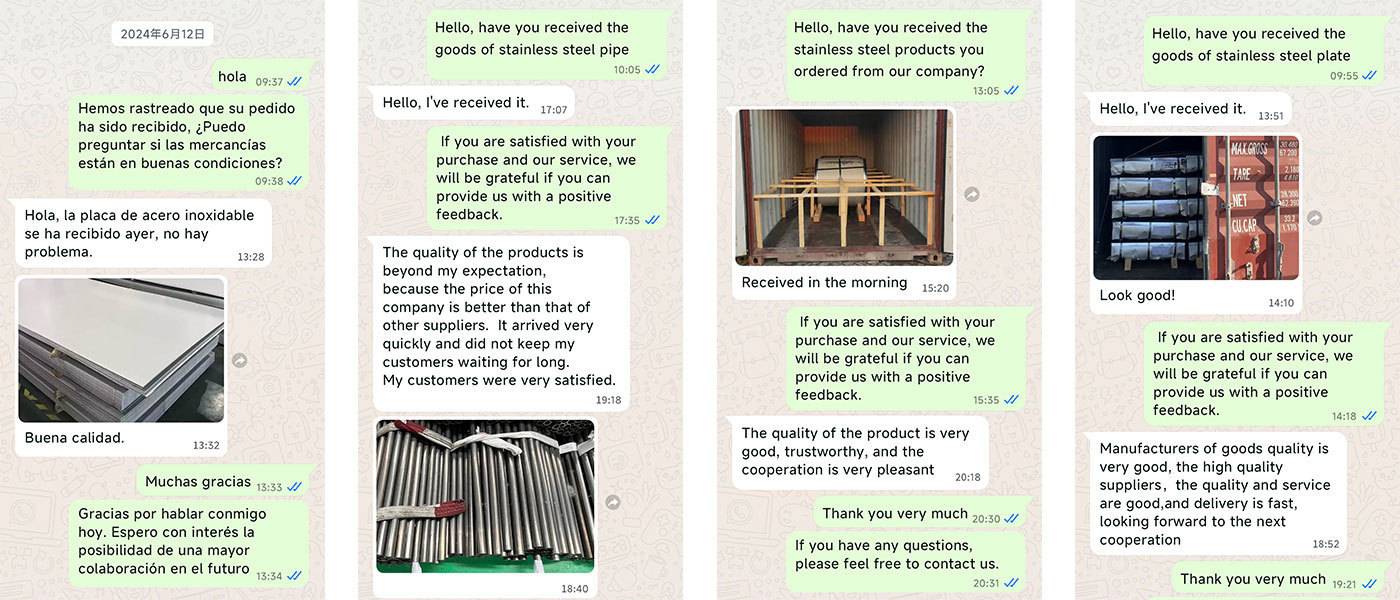

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER