PRODUCTS DESCRIPTION

347 stainless steel pipe is generally more durable than other stainless steel materials under high temperatures. This makes it an ideal option for high temperature environments. 347 stainless steel pipe maintains its strength and durability without embrittlement or fatigue In high-temperature settings. 347 stainless steel pipe also has excellent corrosion resistance. Its ability to remain stable in corrosive environments with strong acids and bases such as chloride ions and sulfide ions explains why it is commonly used in the chemical and petroleum industries. In addition, 347 stainless steel also has good processing properties. It can be processed into various shapes through forging, quenching, annealing and cold working. Overall speaking, 347 stainless steel pipe is popular in industries such as chemical, petroleum, pharmaceutical and food processing for its high temperature durability, corrosion resistance and processability.

Product Parameters

Product Name | 347 Stainless Steel Pipe | |

Type | Steel Pipe | |

Outer diameter | Round Tube | 4mm-200mm |

Square Tube | 10*10mm-100*100mm | |

Rectangular Tube | 10*20mm-50*100mm | |

Wall Thickness | 0.6mm-6.0mm | |

Length | 1-6 meters, Length can be customized | |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. | |

Scope of Application | Common applications for stainless steel pipes include food processing, Textile operations, Breweries, Water treatment plants, Oil and gas processing, Fertilizers and pesticides, Chemical applications, Construction, Pharmaceuticals, Auto parts, etc. | |

Certificate | ISO, SGS, BV, etc. | |

Production Technology | Hot Rolling, Cold Rolling | |

Edge Processing | Edging, Trimming | |

Chemical Composition

C | Si | Mn | Cr | Ni | S | P |

≤ 0.08 | ≤ 0.75 | ≤ 2.0 | 18.0~20.0 | 9.0~13.0 | ≤ 0.03 | ≤ 0.04 |

Mechanical Properties

Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

≥515 | ≥205 | ≥ 40 | ≤ 201HB;≤ 95HRB |

Physical Performance

Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

7.97 | 193 | 16.0 | 16.3 | 72 |

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

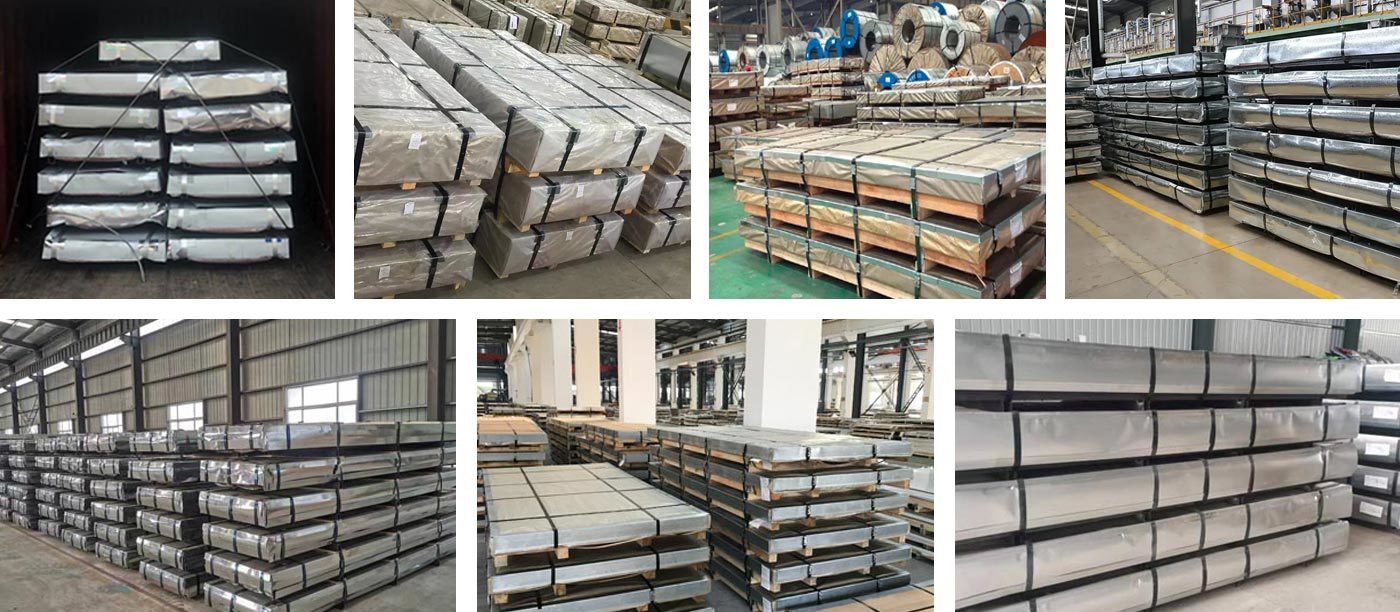

PACKING AND DELIVERY

PRODUCT TESTING

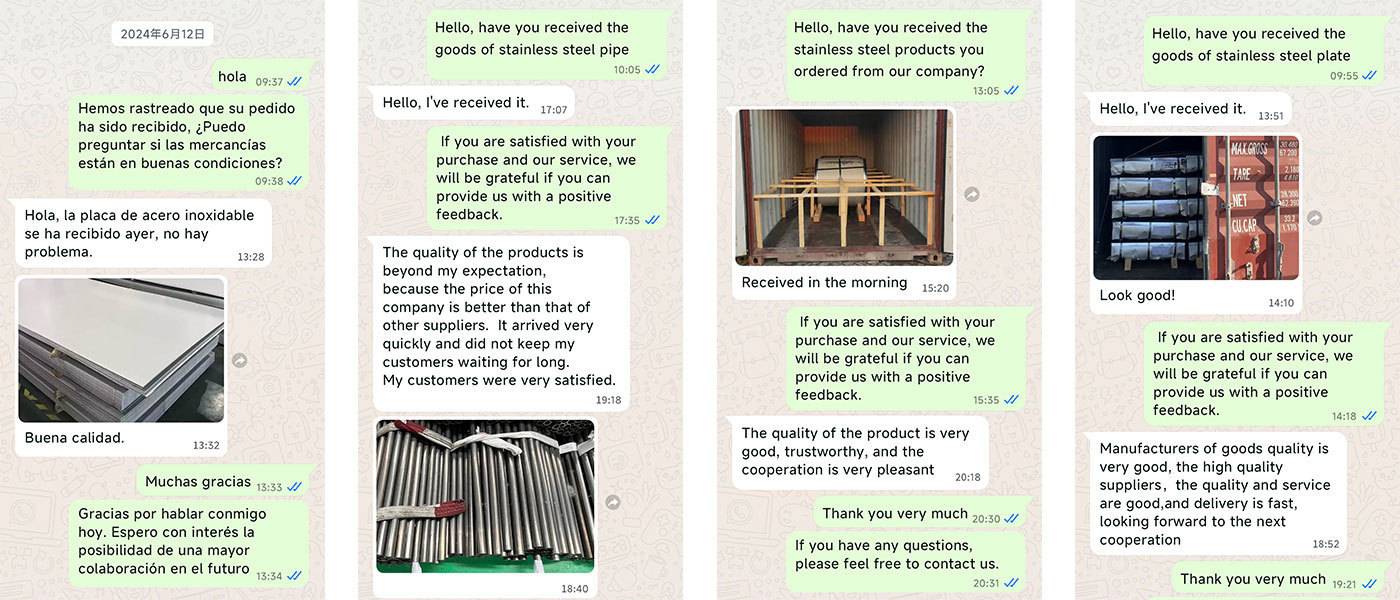

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER