PRODUCTS DESCRIPTION

By definition, seamless tubes are completely homogenous tubes, the properties of which give seamless tubing more strength, superior corrosion resistance, and the ability to withstand higher pressure than welded tubes. This makes them more suitable in critical applications in harsh environments, but it comes with a price.

Product Parameters

Product Name | Stainless Steel Seamless Pipe | |

Type | Steel Pipe | |

Outer diameter | Round Tube | 4mm-200mm |

Square Tube | 10*10mm-100*100mm | |

Rectangular Tube | 10*20mm-50*100mm | |

Wall Thickness | 0.6mm-6.0mm | |

Length | 1-6 meters, Length can be customized | |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. | |

Scope of Application | Common applications for stainless steel pipes include food processing, Textile operations, Breweries, Water treatment plants, Oil and gas processing, Fertilizers and pesticides, Chemical applications, Construction, Pharmaceuticals, Auto parts, etc. | |

Certificate | ISO, SGS, BV, etc. | |

Production Technology | Hot Rolling, Cold Rolling | |

Edge Processing | Edging, Trimming | |

Stainless Steel Seamless Pipe Manufacturing

Knowing that distinction can also help in determining which tubing is best for a given application, welded or seamless. The method of manufacturing welded and seamless tubing is evident in their names alone. Seamless tubes are as defined – they do not have a welded seam. The tubing is manufactured through an extrusion process where the tube is drawn from a solid stainless steel billet and extruded into a hollow form. The billets are first heated and then formed into oblong circular molds that are hollowed in a piercing mill. While hot, the molds are drawn through a mandrel rod and elongated. The mandrel milling process increases the mold’s length by twenty times to form a seamless tube shape. Tubing is further shaped through pilfering, a cold rolling process, or cold drawing.

Stainless Steel Seamless Pipe Benefits

● Stronger

● Superior corrosion resistance

● Higher pressure resistance

Stainless Steel Seamless Pipe Applications

● Oil and gas control lines

● Chemical injection lines

● Below sea safety valves

● Chemical processing plant steam and heat trace bundles

● Fluid and gas transfer

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

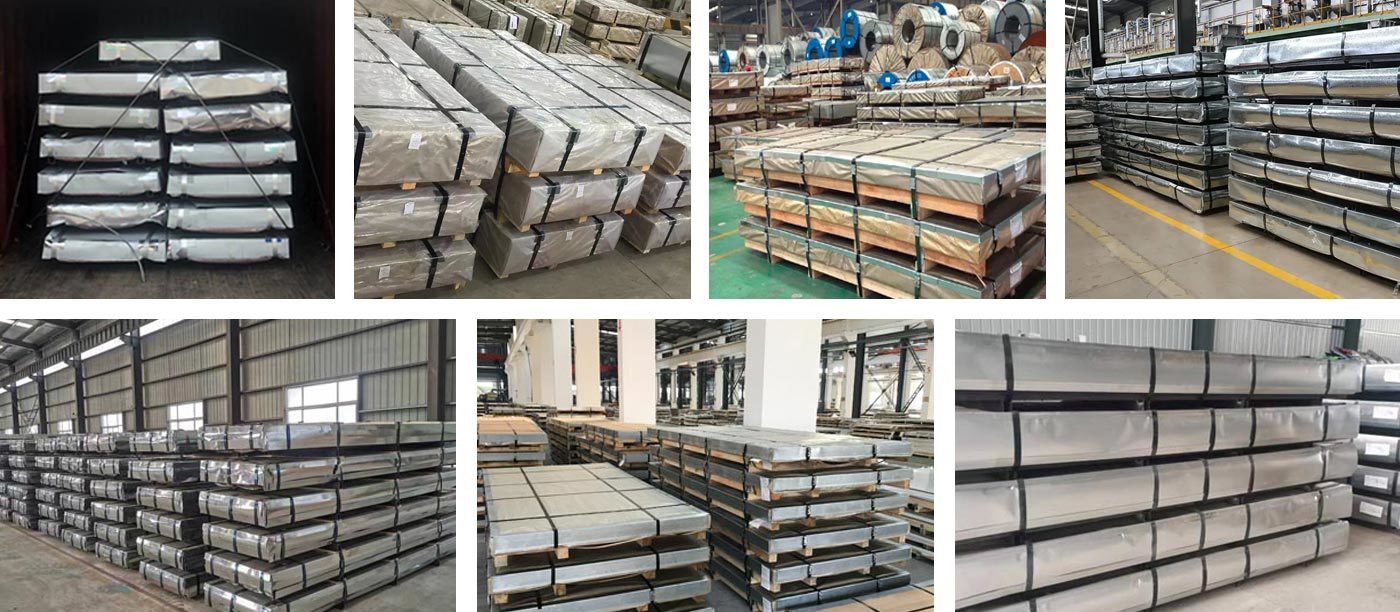

PACKING AND DELIVERY

PRODUCT TESTING

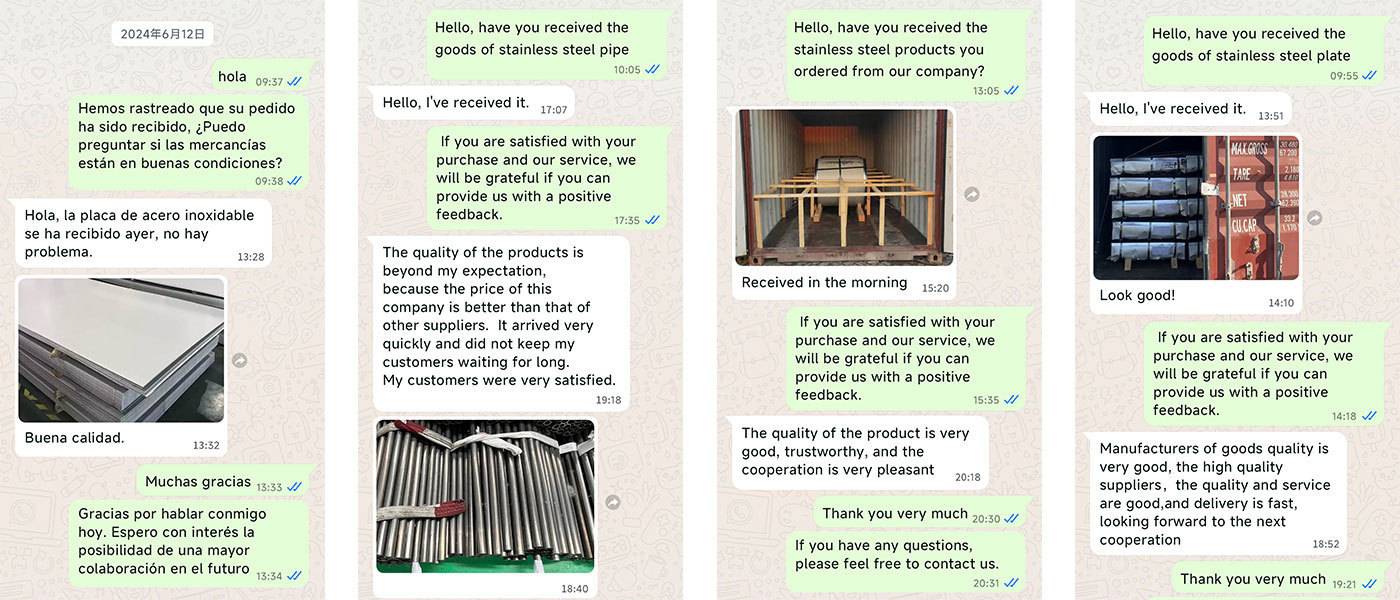

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER