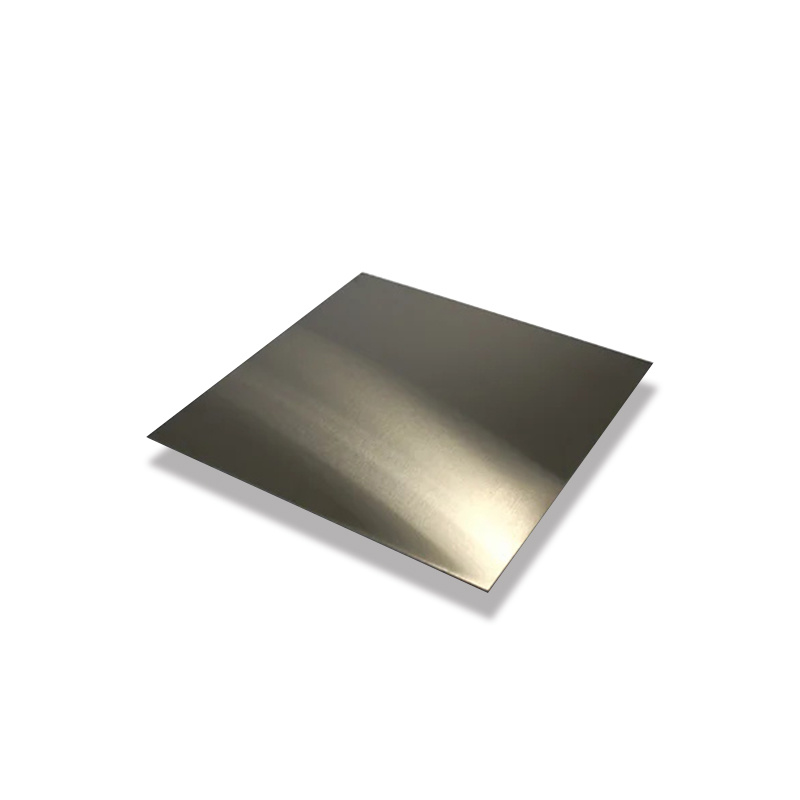

PRODUCTS DESCRIPTION

The yield strength of 2205 Duplex stainless steel is more than twice that of ordinary austenitic stainless steel, and it has enough plastic toughness required for molding. The wall thickness of storage tanks or pressure vessels made of duplex stainless steel is 30-50% less than that of commonly used austenite, which is conducive to reducing costs. Moreover, it has good local corrosion resistance, and compared with austenitic stainless steel with similar alloy content, its wear corrosion resistance and fatigue corrosion performance are better than austenitic stainless steel. Whether under dynamic load or static load conditions, 2205 duplex stainless steel has a higher energy absorption capacity than austenitic stainless steel, which has obvious advantages for structural parts to cope with emergencies such as collisions, explosions, etc..

Product Parameters

Product Name | 2205 Duplex Stainless Steel Plate |

Type | Plate |

Thickness | 0.3mm-200mm |

Length | 2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. |

Width | 40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

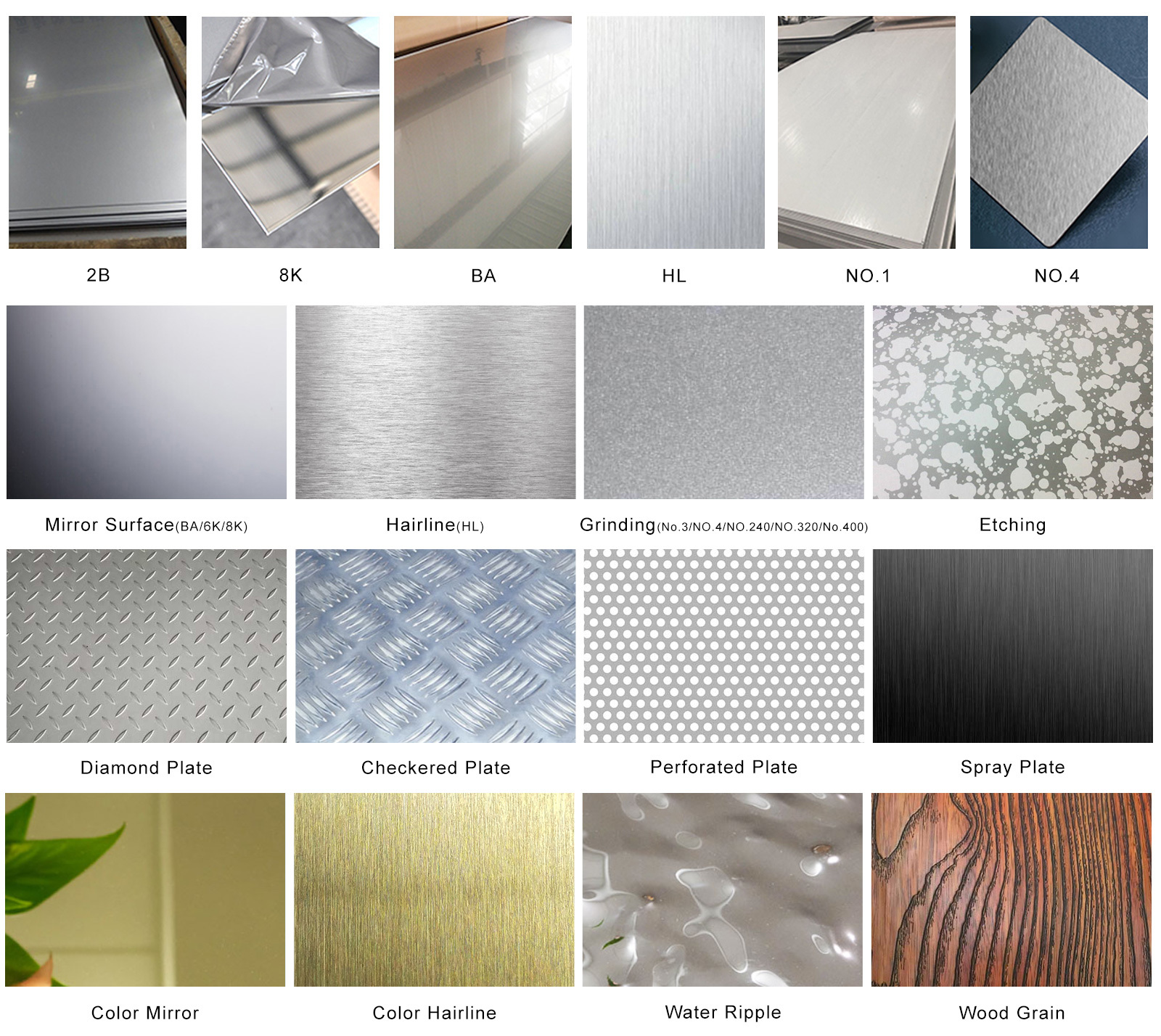

Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

Scope of Application | Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

Certificate | ISO, SGS, BV, etc. |

Production Technology | Hot Rolling, Cold Rolling |

Edge Processing | Edging, Trimming |

Chemical Composition

C | Si | Mn | Cr | Ni | Mo | S | P |

≤ 0.03 | ≤1.0 | ≤ 2.0 | 21.0~23.0 | 4.5~6.5 | 2.5~3.5 | ≤ 0.02 | ≤ 0.03 |

Mechanical Properties

Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

≥620 | ≥450 | ≥25 | ≤ 293HB |

Physical Performance

Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

7.88 | 190 | 13.7 | 19.0 | 80 |

Surface Selection

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

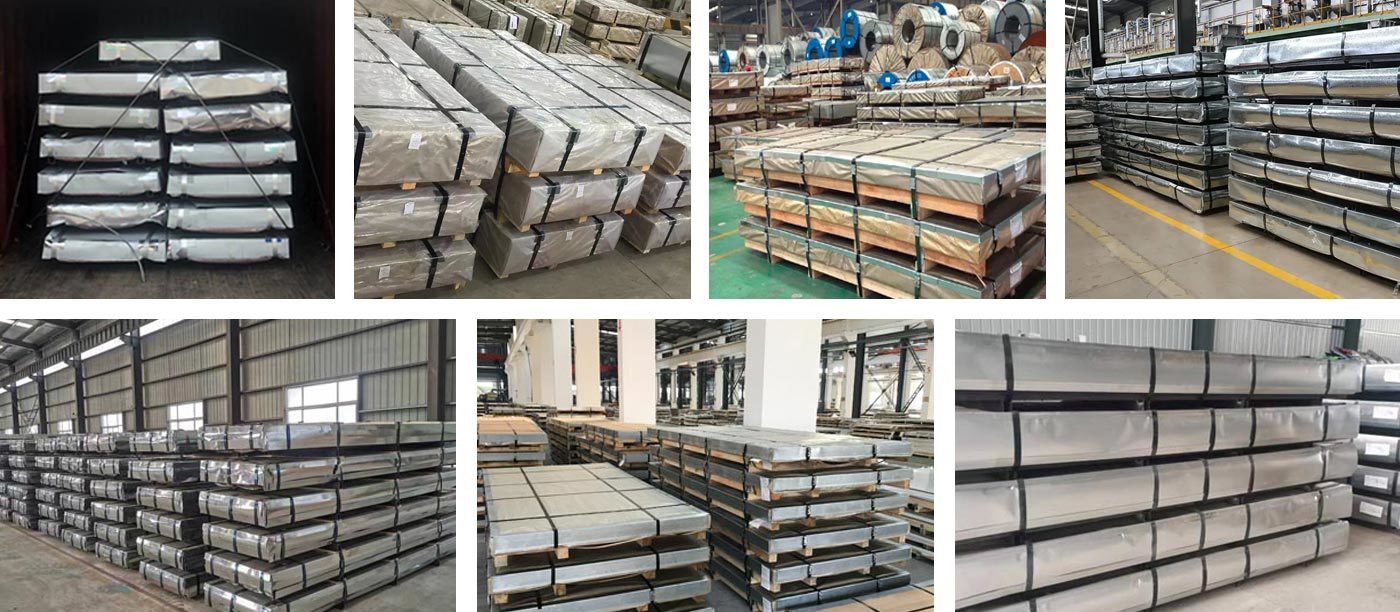

PACKING AND DELIVERY

PRODUCT TESTING

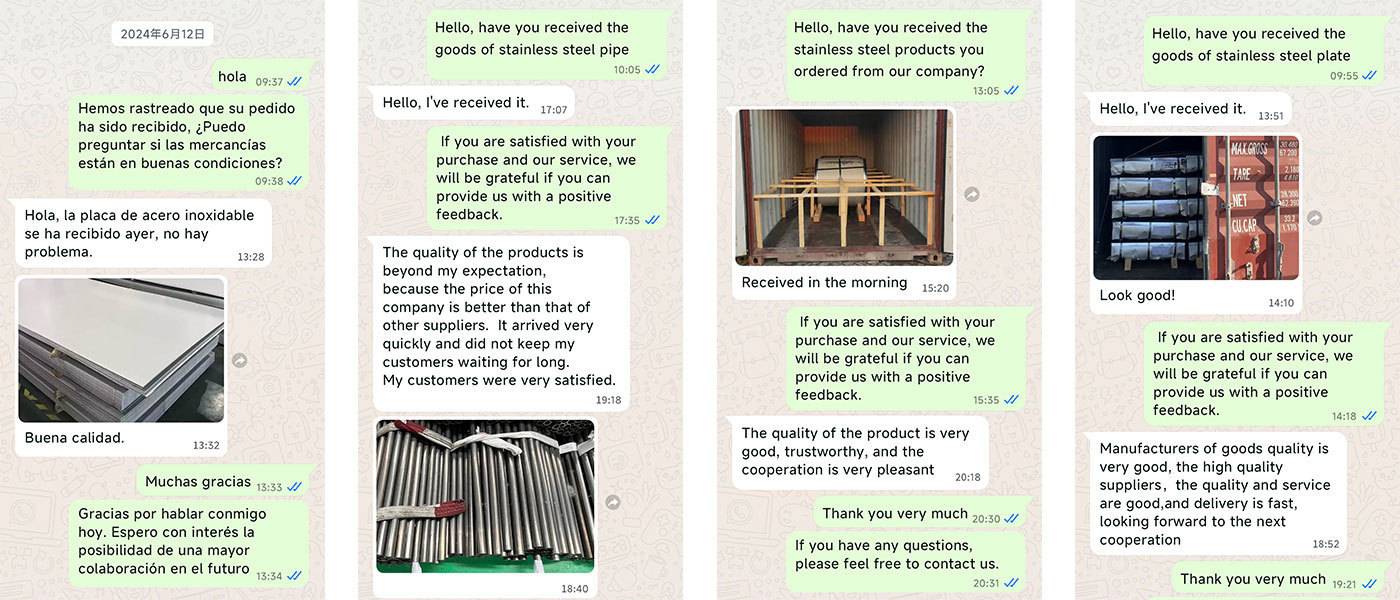

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER