PRODUCTS DESCRIPTION

Reinforced concrete is an important construction material. Highway bridges, car parks, houses, office buildings, gulleys are examples of reinforced concrete structures. In many cases, its steel reinforcement does not need any external corrosion protection to avoid corrosion. The highly alkaline environment of concrete forms a thin oxide layer on the steel surface which protects or “passivates” the steel against further corrosion.

Galvanized rebar is the new material that results after steel rods or wires are hot-dipped into zinc to create a protective coating. This coating protects the steel itself from the elements, making it stronger and more resistant to erosion.

How does galvanized rebar compare to epoxy-coated rebar?

Epoxy-coated rebar was a popular coated steel option before galvanized materials grew in popularity in the US. Epoxy was originally chosen to coat steel as it was rust-resistant and provided some protection from the outside elements. But, the epoxy coated rebar proved to be fragile. Its fragility allowed for water to leak through to the steel and cause catastrophic corrosion.

Galvanized rebar proved to be more up to the task. Not only does its tough coating sustain bumps and scratches with little to no compromise, but it is also able to self-heal. The self-healing properties of the zinc coating make it even stronger where there is a scratch or dent. When water hits it, it actively resists the corrosion.

How long can galvanized rebar last before it needs to be replaced or repaired?

Galvanized steel has a decades-long lifespan. Often the projects that use it need repairs or upgrades before the rebar itself needs attention. When the rebar is re-exposed, it’s like new, even decades later. At times, the protective coating can even become harder because of the self-healing, chemical reaction.

Scope of Application

Galvanized rebar is a popular choice for building transportation infrastructure. This is because galvanizing rebar makes it one of the strongest and most corrosion-resistant options available. It will stand the test of the decades and hold up in harsh conditions. This also makes it a great choice for work on monuments, museums, and government buildings.

Due to its shiny coating, galvanized rebar is a popular choice for projects where the durability and the aesthetic are of equal importance. Its rust-resistance guarantees the beauty of your build will remain years after its completion.

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

PACKING AND DELIVERY

PRODUCT TESTING

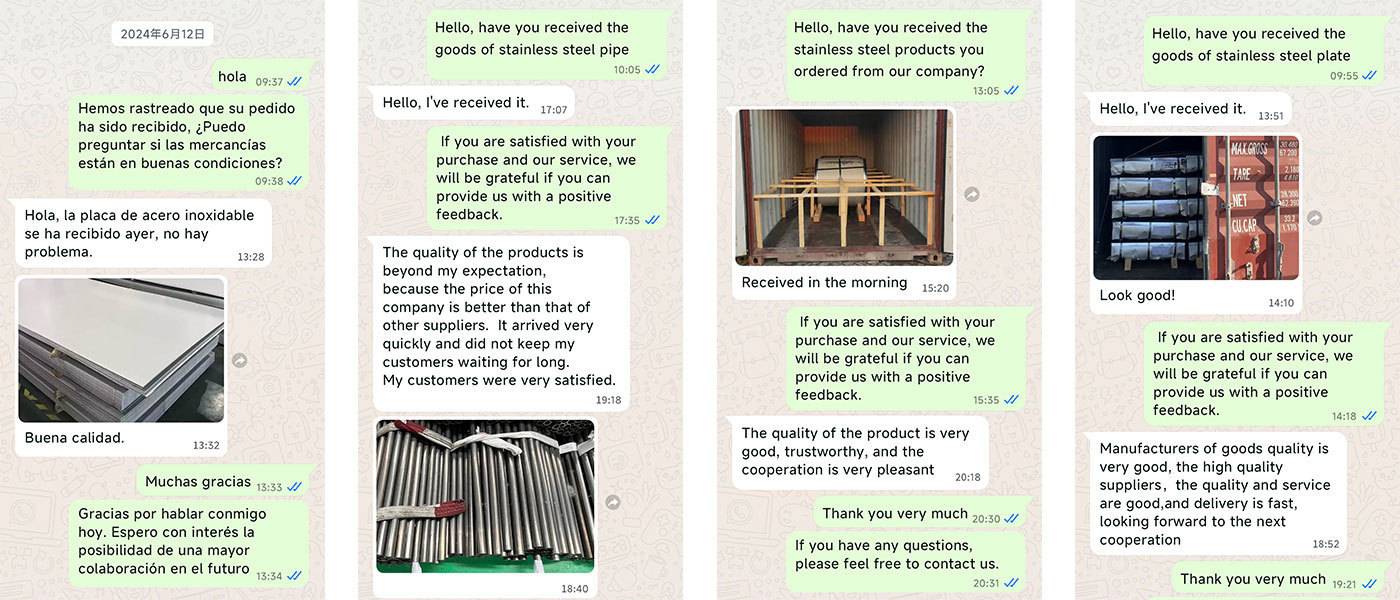

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER