PRODUCTS DESCRIPTION

Hastelloy X bar has excellent corrosion resistance and can be used for a long time in various corrosive environments. This is because a large number of alloying elements are added to the alloy, such as nickel, chromium, molybdenum, etc. These elements form a dense oxide film on the surface of the alloy, which can effectively resist the erosion of various chemical substances. Hastelloy X bar has excellent high-temperature strength and can maintain high strength and hardness in high-temperature environments. This is because the alloying elements in the alloy can form strengthening molybdenum, which improves the tensile strength and yield strength of the alloy. Hastelloy X has good processing properties and can be used for casting, forging, rolling and other processing processes.

Product Parameters

Product Name | Hastelloy X Bar | |

Outer Diameter | Round Bar | 4mm-500mm |

Hexagon Bar | 18mm-57mm (11/16″ to 2-3/4″) | |

Square Bar | 18mm-47mm (11/16″ to 1-3/4″) | |

Flat Steel | 1/2 "to 10", Thickness: 2mm-150mm, Can provide customized | |

Length | 1-6 meters, Length can be customized | |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, NO.4, BA, etc. | |

Certificate | ISO, SGS, BV | |

Production Technology | Hot Rolling, Cold Rolling | |

Chemical Composition

C | Si | P | S | Cr | Mn | Fe | Co | Ni | Mo | W |

0.05 - 0.15 | 1.0 max | 0.04 | 0.03 | 20.5 - 23.0 | 1.0 max | 17.0 - 20.0 | 0.5 - 2.5 | Remainder | 8.0 - 10.0 | 0.2 - 1.0 |

Mechanical Properties

Tensile Strength (ksi) | 0.2% Yield Strength (ksi) | Elongation% in 2 inches |

95 | 35 | 35 |

Physical Performance

Units | Temperature in°C | |

Density | 8.22 g/cm³ | 22°C |

Specific Heat | 0.116 Kcal/kg. | Room |

Melting Range | 1260-1355°C | - |

Modulus of Elasticity | 205 KN/mm² | Room |

Electrical Resistivity | 118.3 µΩ.cm | 22° |

Coefficient of Expansion | 13.9 µm/m °C | 26 - 93° |

Thermal Conductivity | 9.1 w/m-° K | 21° |

Scope of Application

Hastelloy X is used in gas turbines, petrochemicals, industrial furnaces, heat treatment equipment, nuclear engineering, jet engine combustion chambers, cabin heaters, turbine exhaust components, etc.

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

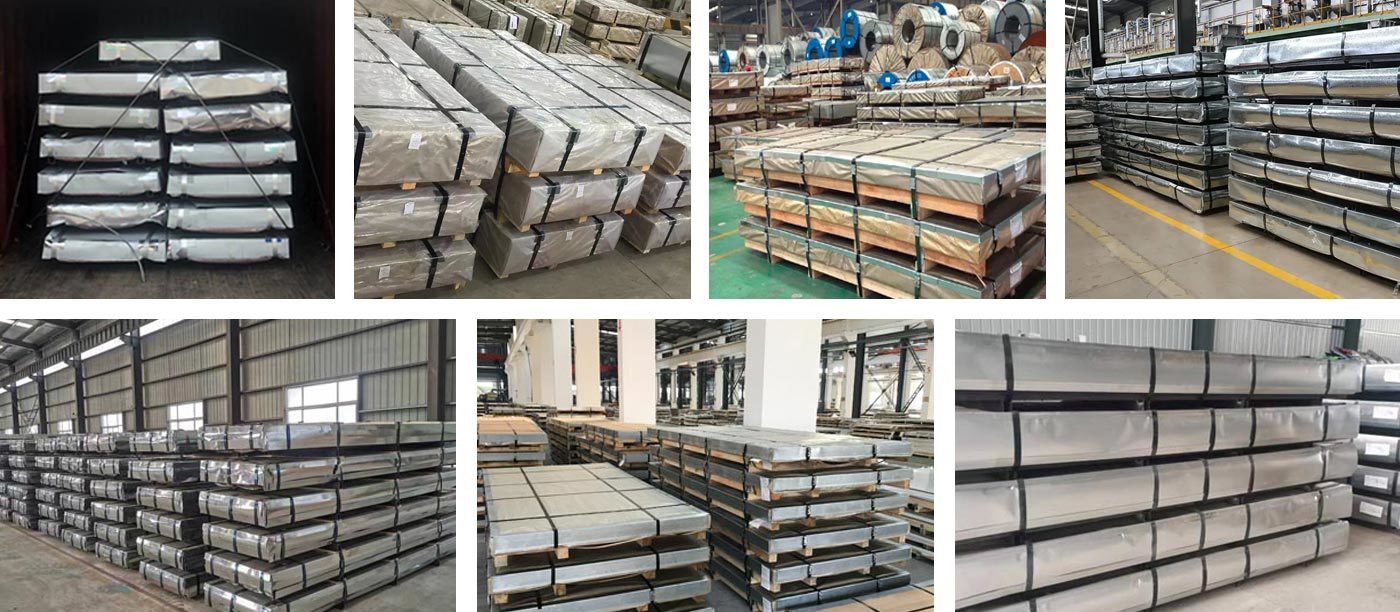

PACKING AND DELIVERY

PRODUCT TESTING

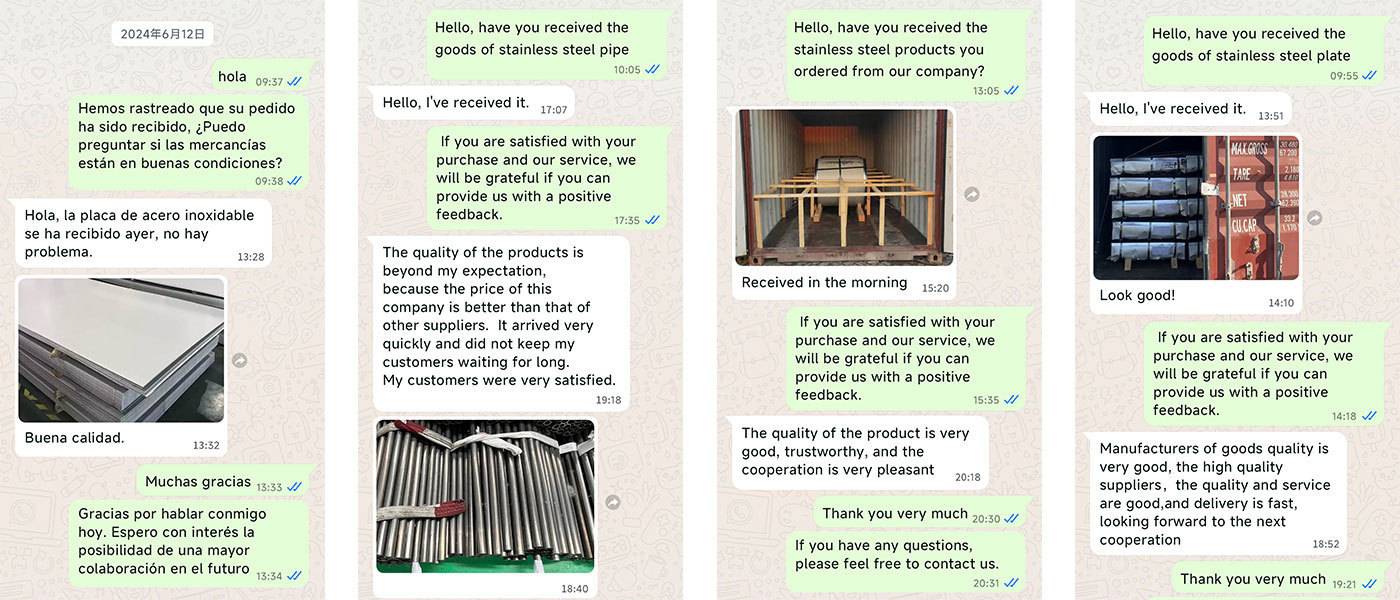

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER