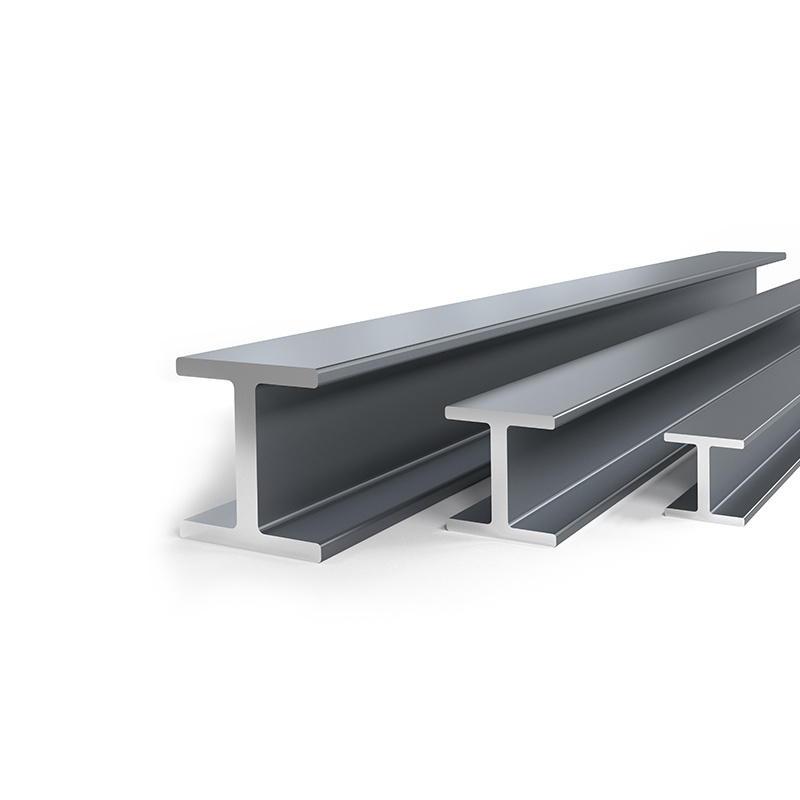

PRODUCTS DESCRIPTION

The strength of Inconel 625 pipe comes from the solid solution strengthening effect of molybdenum and niobium contained in the nickel-chromium alloy. These elements also give the alloy excellent corrosion-resistant properties. While the pipe is designed for strength in high-temperature environments, its highly alloyed composition gives it a high degree of resistance to general corrosion as well as resistance to a wide range of oxidizing and non-oxidizing environments. The chromium and molybdenum content make the pipe highly resistant to corrosion spots caused by chloride ions, and the high nickel content steps up the alloy's resistance to chloride stress corrosion cracking. The material is highly formable and easier to weld than many nickel-based alloys. Even under welded conditions, the pipe still has the ability to resist intergranular corrosion, aside from corrosion and oxidation resistance.

Product Parameters

Product Name | Inconel 625 Pipe | |

Outer Diameter | Round Pipe | 4mm-200mm |

Square Pipe | 10*10mm-100*100mm | |

Rectangular Pipe | 10*20mm-50*100mm | |

Wall Thickness | 0.6mm-6.0mm | |

Length | 1-6 meters, Length can be customized | |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, No.4, BA, etc. | |

Certificate | ISO, SGS, BV | |

Production Technology | Hot Rolling, Cold Rolling | |

Chemical Composition

C | Mg | Al | Si | P | S | Ti | Cr | Fe | Co | Ni | Mo | Cb (Nb Ta) |

0.1 max | 0.5 max | 0.4 max | 0.5 max | 0.015 max | 0.015 max | 0.4 max | 20.00 - 23.00 | 5.0 max | 1.0 max | 58.0 min | 8.0 - 10.0 | 3.15 - 4.15 |

Mechanical Properties

Tensile Strength (ksi) | 0.2% Yield Strength (ksi) | Elongation% in 2 inches |

120 | 60 | 30 |

Physical Performance

Units | Temperature in°C | |

Density | 8.44 g/cm³ | Room |

Specific Heat | 0.098 Kcal/kg.C | 21° |

Melting Range | 1290-1350°C | - |

Modulus of Elasticity | 207.5 KN/mm² | 21° |

Electrical Resistivity | 129 µΩ.cm | 21° |

Coefficient of Expansion | 12.8 µm/m °C | 21 - 93° |

Thermal Conductivity | 9.8 w/m-° K | 21° |

Scope of Application

This alloy is resistant to a variety of severe corrosive environments, especially to pitting and crevice corrosion. Some applications of Inconel 625 are used as part of chemical processing, aerospace, and marine engineering, pollution control equipment, and nuclear reactors.

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

PACKING AND DELIVERY

PRODUCT TESTING

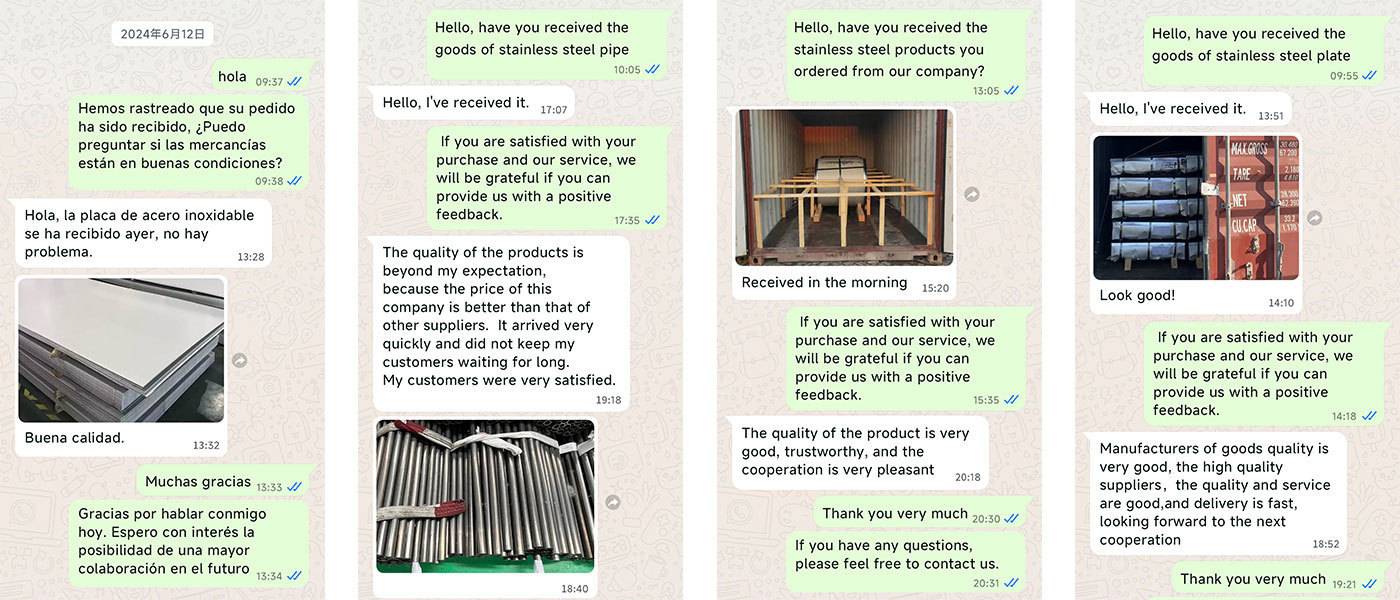

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER