PRODUCTS DESCRIPTION

A36 is a carbon structural steel whose chemical composition and mechanical properties strictly conform to American ASTM standards. A36 steel bar mainly consists of iron, carbon, silicon, manganese, phosphorus, sulfur and other elements. Iron constitutes more than 99% of the entire chemical composition. Its carbon content proportion is relatively high, around 0.2%, ensuring that the steel has a certain hardness and toughness. The addition of silicon, manganese and other elements enhances the strength and toughness of steel. Phosphorus and sulfur are low so that the steel bar has good welding performance and corrosion resistance. A36 steel bar is used for welded, bolted or riveted construction of bridges and buildings, as well as for general structural purposes. Due to its lowest yield point, A36 can be used to design lighter-weight structures and equipment, and provide good weldability.

Product Parameters

Product Name | A36 Round Steel Bar | |||

Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI, etc. | |||

Common Round Bar Specifications | 3.0-50.8 mm, Over 50.8-300mm | |||

Flat Steel Common Specifications | 6.35x12.7mm, 6.35x25.4mm, 12.7x25.4mm | |||

Hexagon Bar Common Specifications | AF5.8mm-17mm | |||

Square Bar Common Specifications | AF2mm-14mm, AF6.35mm, 9.5mm, 12.7mm, 15.98mm, 19.0mm, 25.4mm | |||

Length | 1-6meters, Size Accept Custom | |||

Diameter(mm) | Hot Rolling Round Bar | 25-600 | Cold Rolling Square Bar | 6-50.8 |

Hot Rolling Square Bar | 21-54 | Cold Rolling Hexagon Bar | 9.5-65 | |

Cold Rolling Round bar | 6-101.6 | Forged Rebar | 200-1000 | |

Surface Process | Bright, Polished, Black | |||

Other Services | Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. | |||

Chemical Composition

C | Cu | Fe | Mn | P | Si | S |

0.25-0.290 | 0.20 | 98.0 | 1.03 | 0.040 | 0.280 | 0.050 |

Mechanical Properties

A36 | Limit Tensile Strength | Tensile Strength, Yield Strength | Elongation at Break (Unit: 200mm) | Elongation at Break (Unit: 50mm) | Modulus of Elasticity | Bulk Modulus (Typical for Steel) | Poisson's Ratio | Shear Modulus |

Metric | 400-550 MPa | 250 MPa | 20.0 % | 23.0 % | 200 GPa | 140 GPa | 0.260 | 79.3 GPa |

Imperial | 58000-79800 psi | 36300 psi | 20.0 % | 23.0 % | 29000 ksi | 20300 ksi | 0.260 | 11500 ksi |

Physical Performance

Physical Performance | Metric | Imperial |

Density | 7.85 g/cm3 | 0.284 lb/in3 |

Scope of Application

Bolted, riveted or welded structures for bridges, buildings and oil drilling rigs.

Used for forming storage tanks, silos, bearing plates, fixtures, rings, templates, fixtures, sprockets, cams, gears, bottom plates, forgings, decoration engineering, piles, brackets, automobiles and agricultural equipment, frames, mechanical parts, etc.

Equivalent Material

National Standard GB | European Standard EN | American Standard ASTM | German Standard DIN,WNr | Japanese Standard JIS | French Standard AFNOR | British Standard BS | Canada HG |

Q235B | S235JR | A283C | St37-2 | SM400A | E24-2 | 40A/40B | 230G |

Italy UNI | India IS | Switzerland SS | Australia ONORM | Norway NS | Spain UNE | International Standards ISO | Portugal NP |

Fe360B | IS2062 | 1311/1312 | RSt360B | NS12123 | AE235B-FN | E235B/Fe360B | FE360-B |

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

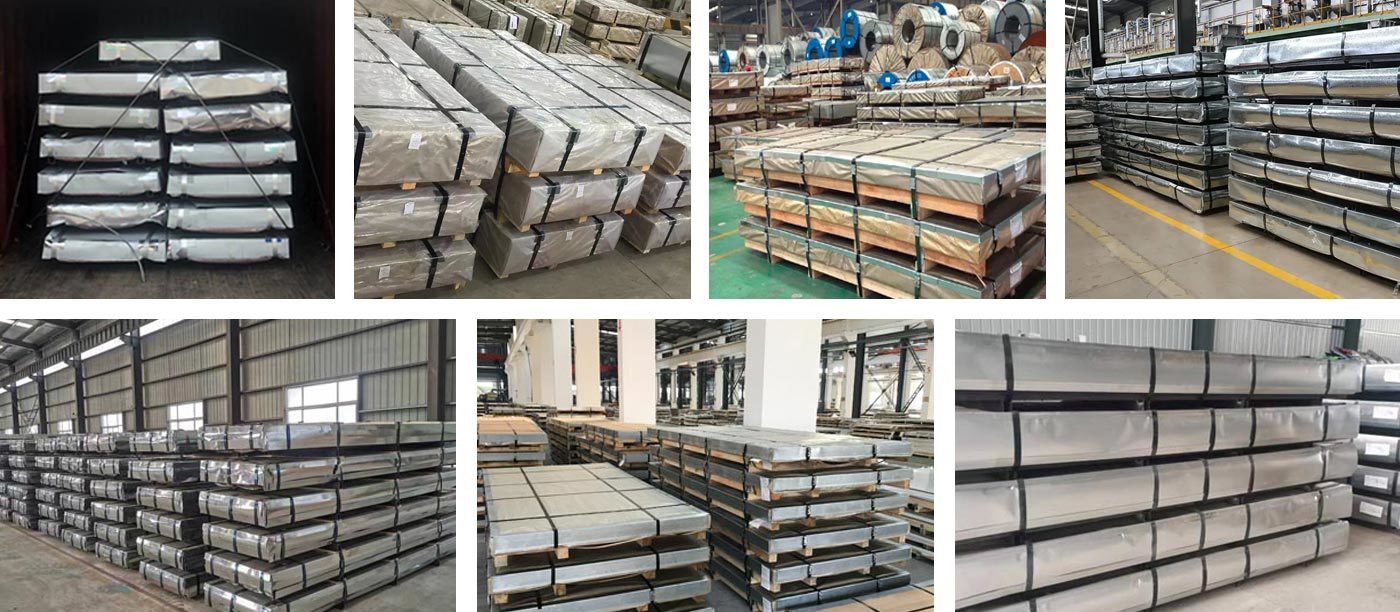

PACKING AND DELIVERY

PRODUCT TESTING

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER