PRODUCTS DESCRIPTION

410 stainless steel is a type of martensitic stainless steel with a chromium content of 11.5% and excellent corrosion resistance. 410 stainless steel has been quenched, tempered and polished to improve corrosion resistance. And quenching and tempering just makes 410 stainless steel harder. Compared to austenitic stainless steel, martensitic stainless steel is relatively inferior, which is why martensitic stainless steel requires a final heat treatment to be manufactured. Grade 410 stainless steel has the ability to withstand hot gases, steam, food, weak acids and bases, fresh water, and dry air. This steel is hardened for maximum corrosion and heat resistance. 410 stainless steel is a versatile and popular choice in automotive manufacturing due to its many advantages. A key advantage of this material is its high strength, making it ideal for applications requiring durability and wear resistance.

Product Parameters

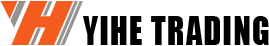

Product Name | 410 Stainless Steel Plate |

Type | Plate |

Thickness | 0.3mm-200mm |

Length | 2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. |

Width | 40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

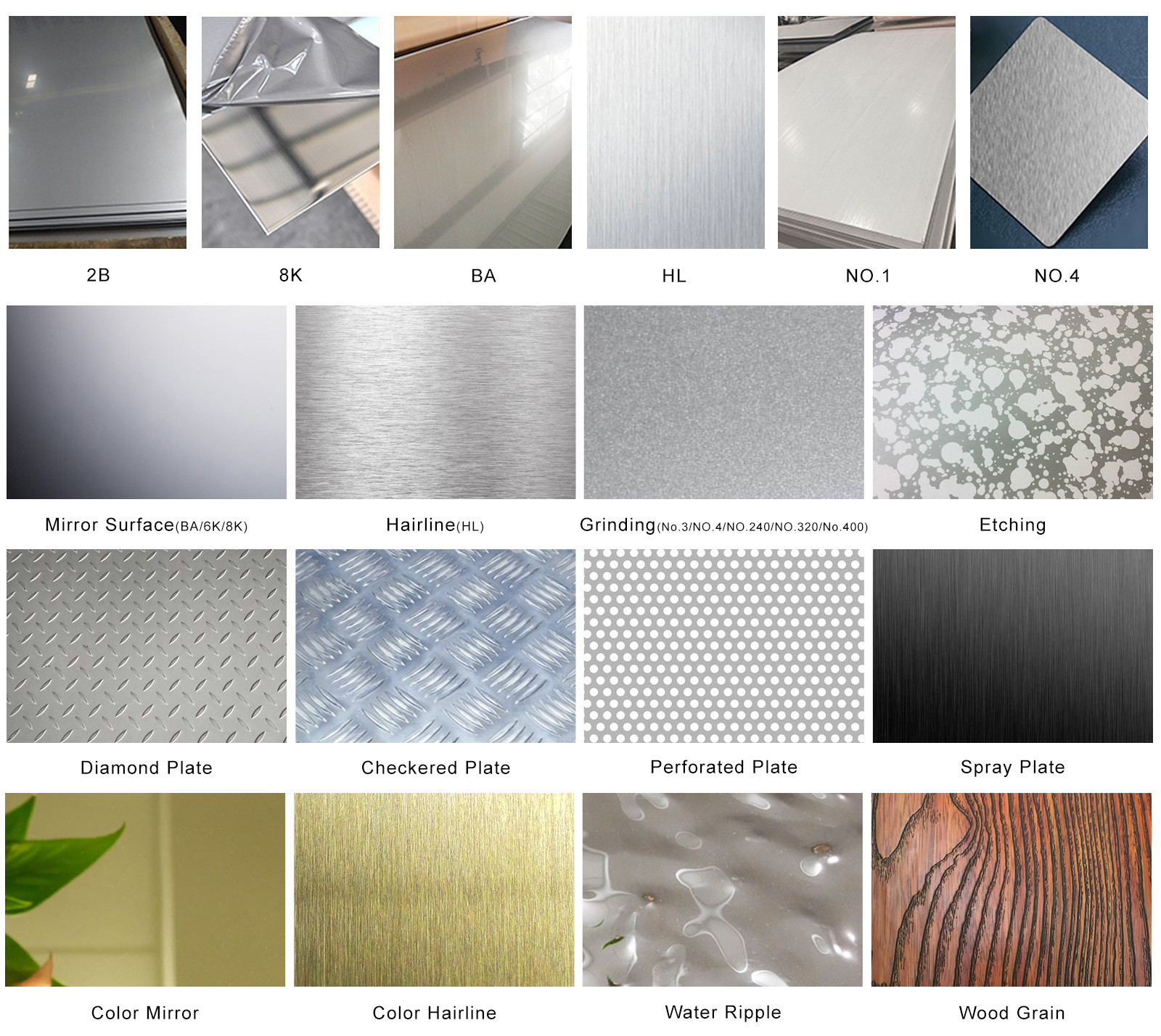

Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

Scope of Application | Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

Certificate | ISO, SGS, BV, etc. |

Production Technology | Hot Rolling, Cold Rolling |

Edge Processing | Edging, Trimming |

Chemical Composition

C | Si | Mn | Cr | Ni | S | P |

≤ 0.15 | ≤1.0 | ≤1.0 | 11.5~13.5 | ≤ 0.5 | ≤ 0.03 | ≤ 0.04 |

Mechanical Properties

Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

≥450 | ≥205 | ≥20 | ≤ 201HB |

Physical Performance

Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

7.74 | 200 | 9.9 | 24.9 | 570 |

Surface Selection

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

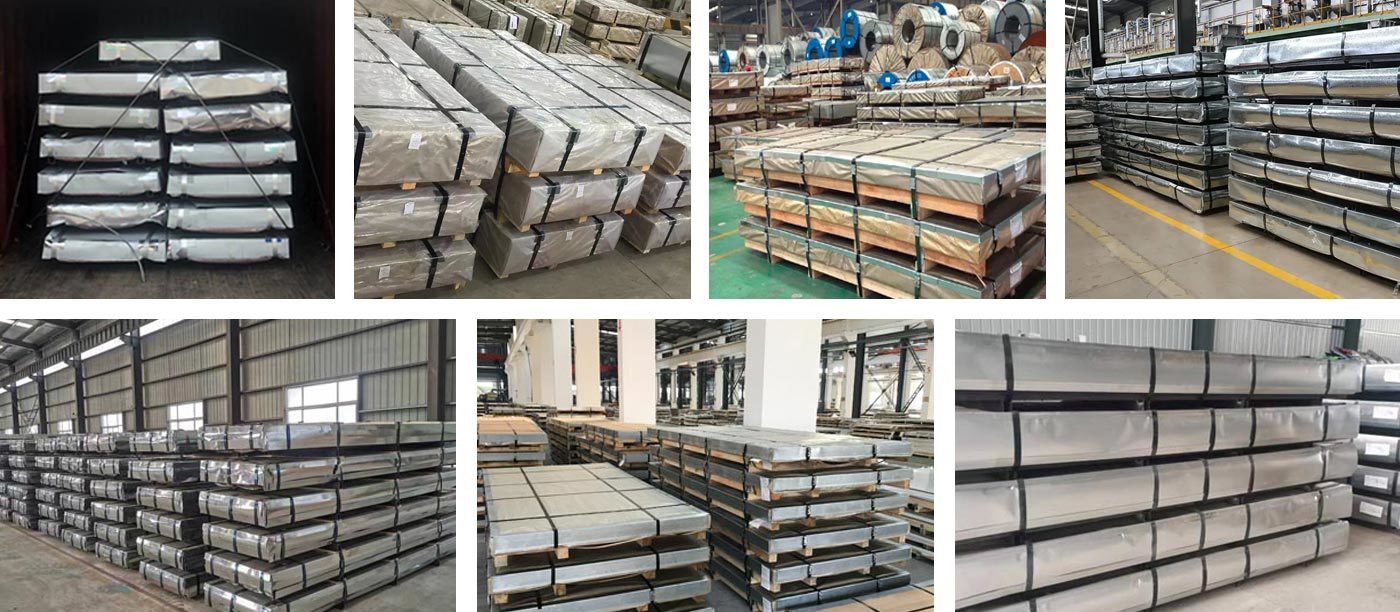

PACKING AND DELIVERY

PRODUCT TESTING

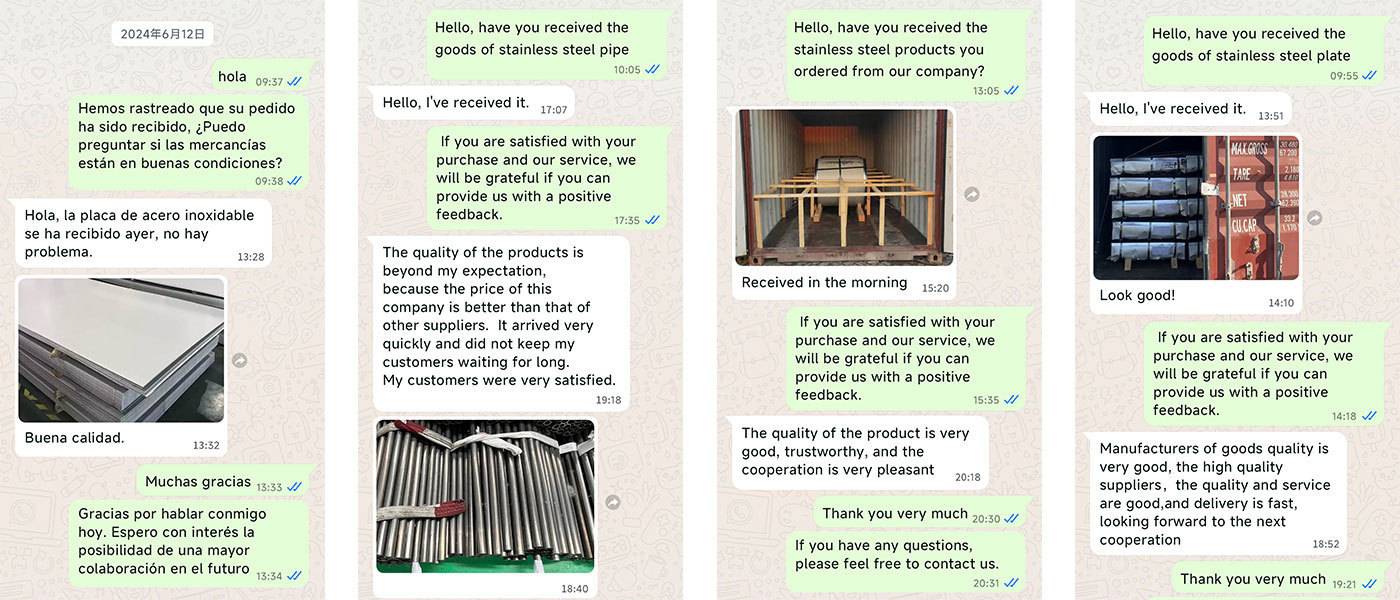

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER