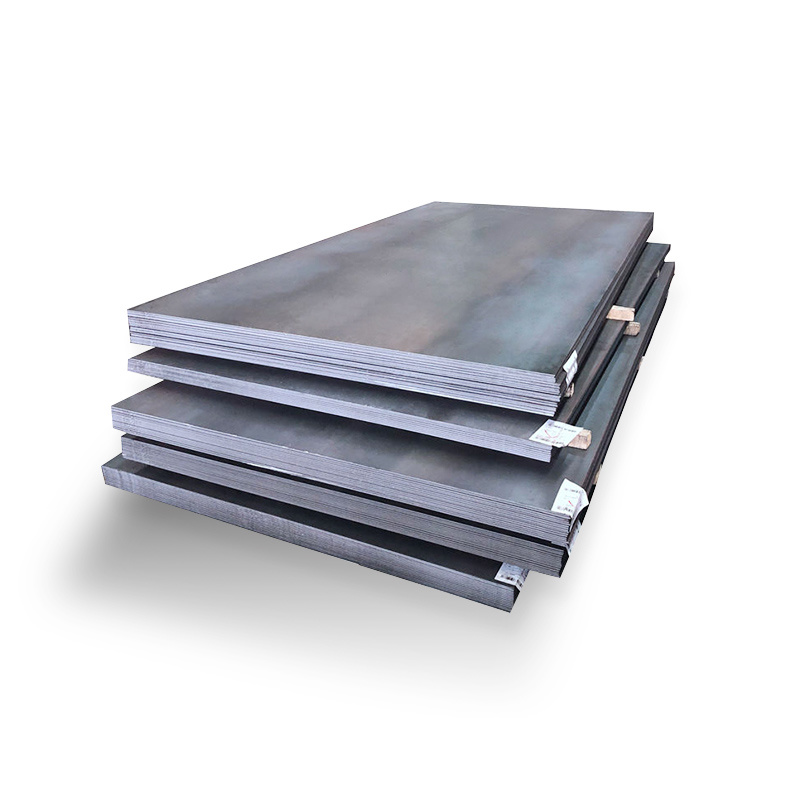

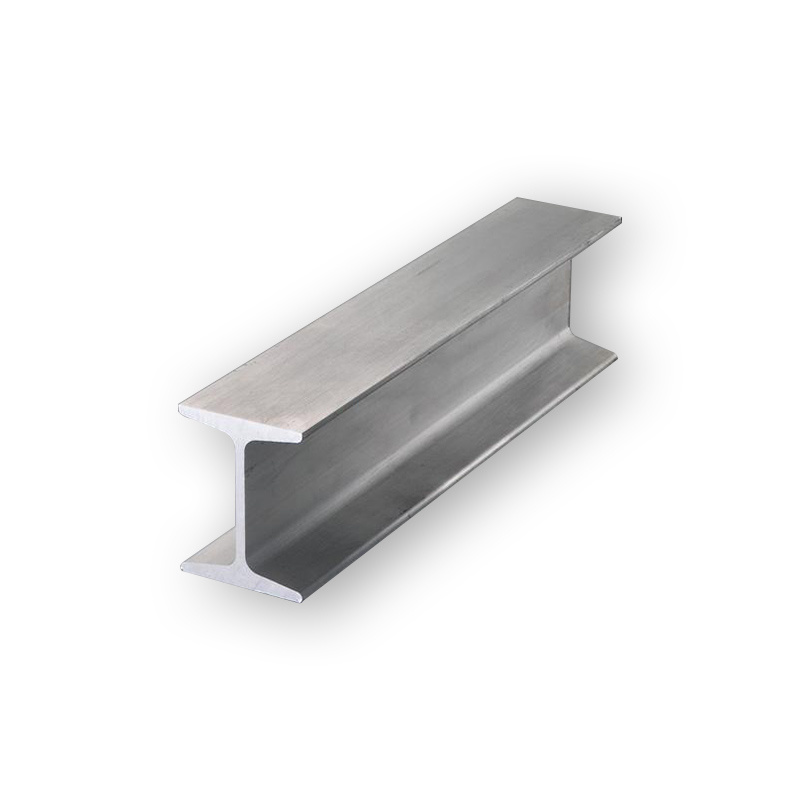

PRODUCTS DESCRIPTION

EN 10083-3:2006 steel is an alloy steel used for quenching and tempering. This standard regulates the technical delivery conditions of alloy steels. Under the steel 50CrMo4, 51CrV4, 20MnB5, 34CrMo4, 42CrMo4, 27MnCrB5-2. EN 10083-3 steel plate has high strength, high toughness and good hardenability. The alloy requires high temperature preheating before welding to eliminate the stress after welding.

Product Parameters

Product Name | 4135/4140/4142/6150 Alloy Plate EN10083-3 |

Production Process | Hot Rolling, Cold Rolling |

Material Standards | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

Width | 100mm-3000mm |

Length | 1m-12m, or Customized Size |

Thickness | 0.1mm-400mm |

Delivery Conditions | Rolling, Annealing, Quenching, Tempered or Standard |

Surface Process | Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

Brand | C | Si max | Mn | P max | S max | Cr | Mo | V |

34CrMo4 | 0.3-0.37 | 0.40 | 0.6-0.9 | 0.025 | 0.035 | 0.9-1.2 | 0.15-0.3 | - |

42CrMo4 | 0.38-0.45 | 0.40 | 0.6-0.9 | 0.025 | 0.035 | 0.9-1.2 | 0.15-0.3 | - |

50CrMo4 | 0.46-0.54 | 0.40 | 0.5-0.8 | 0.025 | 0.035 | 0.9-1.2 | 0.15-0.3 | - |

51CrV4 | 0.47-0.55 | 0.40 | 0.7-1.1 | 0.025 | 0.025 | 0.9-1.2 | - | 0.1-0.25 |

Mechanical Properties

Thickness mm | Re min. N/mm2 | Rm N/mm2 | A min % | From min % | KVb min J |

≤8 | 900 | 1000-1300 | 10 | 40 | - |

8-20 | 750 | 1000-1200 | 11 | 45 | 35 |

20-60 | 650 | 900-1100 | 12 | 50 | 35 |

60-100 | 550 | 800-950 | 13 | 50 | 35 |

100-160 | 500 | 750-900 | 14 | 55 | 35 |

Scope of Application

EN 10083-3 steel plates are used to manufacture tools that require good plasticity and high strength. It is usually selected to manufacture large parts and important parts, such as heavy mechanical shafts, turbine shaft blades, high loads of transmission parts, fasteners, crankshafts, gears, and heavy-duty parts of motor structures.

Equivalent Material

European Standard | American Standard | German Standard | Japanese standard | National Standard | International Standards |

34CrMo4 | 4135 | 34CrMo4 | SCM435H | 35CrMo | 34CrMo4 |

42CrMo4 | 4140, 4142 | 42CrMo4 | SCM440H | 42CrMo | 42CrMo4 |

50CrMo4 | - | 50CrMo4 | - | 50CrMo | 50CrMo4 |

51CrV4 | 6150 | 50CrV4 | SUP10 | 50CrVA | 51CrV4 |

FAQ

Q:What about your price?

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

Q:What certifications do your products have?

A:We have ISO 9001, SGS, EWC and other certifications.

Q:What kind of payment terms would you accept?

A:We always do T/T.30% T/T as deposit,70% T/T as balance.

Q:What is your MOQ?

A:We will provide Original Mill Usually 25 tonnes, but it can be adjusted according to your needs and the actual situation of the inventory.

Q:What is the delivery time?

A:10-15 days

PACKING AND DELIVERY

PRODUCT TESTING

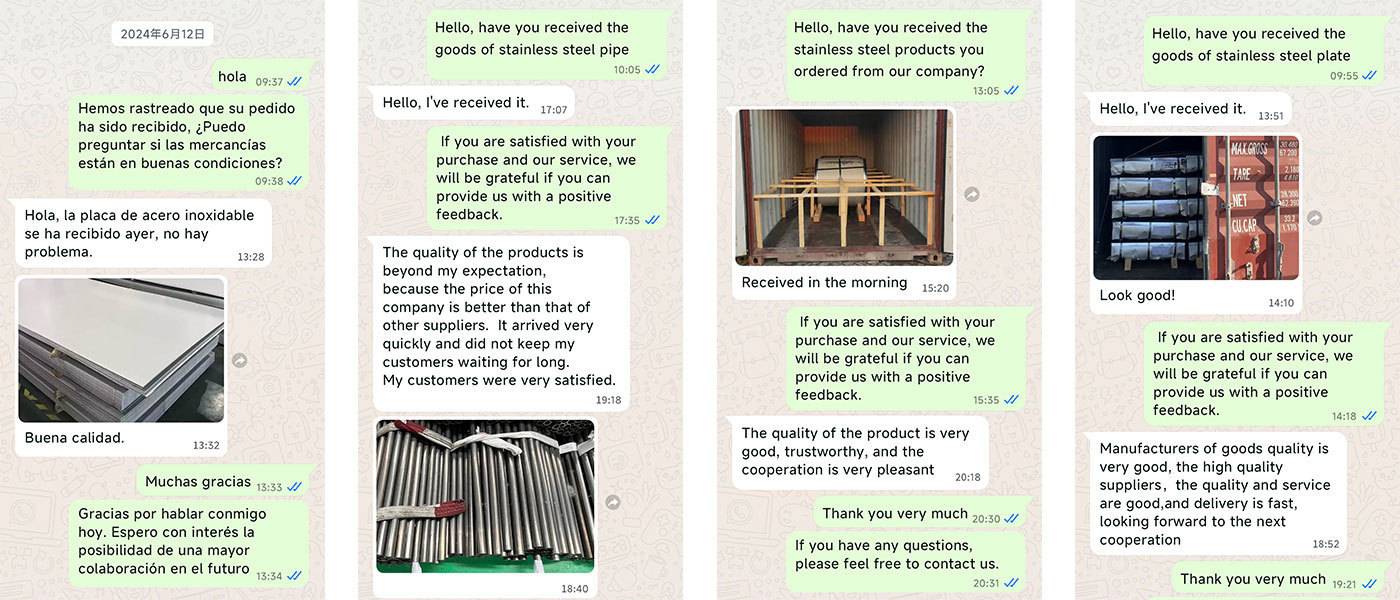

CLIENT FEEDBACK

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

CERTIFICATE OF HONOR

COOPERATIVE PARTNER